PRODUCT PARAMETERS

Description

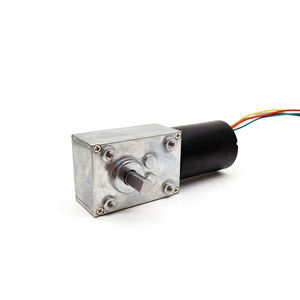

Overview of Good quality cnc processing self lubricating MC nylon POM industrial wear resistant transmission gearbox plastic gear rack

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of Good quality cnc processing self lubricating MC nylon POM industrial wear resistant transmission gearbox plastic gear rack

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: Good quality cnc processing self lubricating MC nylon POM industrial wear resistant transmission gearbox plastic gear racksystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern Good quality cnc processing self lubricating MC nylon POM industrial wear resistant transmission gearbox plastic gear rackmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(Good quality cnc processing self lubricating MC nylon POM industrial wear resistant transmission gearbox plastic gear rack)

Specifications of Good quality cnc processing self lubricating MC nylon POM industrial wear resistant transmission gearbox plastic gear rack

Good Quality CNC Processing Self-Lubricating MC POM Industrial Wear-Resistant Transmission Gearbox Plastic Gear Rack is designed to provide maximum performance and reliability in various industries. The following specifications of this product set it apart from its competitors:

1. High Accuracy: The gears are manufactured using high-quality materials that ensure accurate positioning, which ensures the perfect transmission of power.

2. Wear-resistant Properties: The plastic gears are made with high-strength polypropylene material, making them highly resistant to wear and tear, even under heavy loads.

3. Robust Construction: The gear rack is constructed using sturdy aluminum alloy frames that provide excellent strength and durability.

4. Simple Operation: The machine is equipped with simple controls that make it easy for operators to maintain optimal operation, even with minimal training.

5. Long Operating Life: The transmission gearboxes are designed to last for long periods, providing reliable performance and ensuring smooth operation.

In conclusion, the Good Quality CNC Processing Self-Lubricating MC POM Industrial Wear-Resistant Transmission Gearbox Plastic Gear Rack is an exceptional product that offers superior performance, reliability, and ease of use. It’s suitable for a wide range of industries, including manufacturing, transportation, and construction, and provides peace of mind for both operators and manufacturers alike. Whether you’re looking for a durable, efficient, or cost-effective solution, our product is definitely worth considering.

(Good quality cnc processing self lubricating MC nylon POM industrial wear resistant transmission gearbox plastic gear rack)

Applications of Good quality cnc processing self lubricating MC nylon POM industrial wear resistant transmission gearbox plastic gear rack

Good-quality CNC processing self-lubricating MC nylon POM industrial wear-resistant transmission gearboxes and plastic gear racks are essential components in various industrial applications to ensure optimal performance, reliability, and efficiency. These products offer a wide range of benefits that make them ideal choices for organizations looking to optimize their operations.

Firstly, the use of high-quality CNC processing ensures accurate and consistent machining of parts, resulting in better part quality, reduced waste, and faster cycle times. The self-lubricating nature of MC nylon POM also helps to reduce friction and wear, prolonging the life of the equipment.

Secondly, these gears are designed with industrial wear resistance in mind, making them suitable for and extreme temperatures. The gearboxes can withstand harsh environments, including chemical, oil, and water, while still maintaining excellent performance.

Thirdly, the plastic gear rack is made from lightweight, durable material that can withstand the rigors of industrial usage. It is easy to clean and maintain, reducing maintenance costs and downtime.

Overall, good-quality CNC processing self-lubricating MC nylon POM industrial wear-resistant transmission gearboxes and plastic gear racks provide a range of benefits that can help organizations achieve their goals more efficiently and effectively. Whether you are looking to improve your manufacturing processes or enhance your product reliability, these products are sure to make a significant impact.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Good quality cnc processing self lubricating MC nylon POM industrial wear resistant transmission gearbox plastic gear rack

1. What is CNC Processing and why is it important in the manufacturing process?

CNC (Computer Numerical Control) processing is a high-level technique that uses computers to control complex machinery, including machines used in the production of NC parts. It allows for precise and consistent parting and assembly, reducing errors and increasing efficiency.

2. What are the benefits of using a Good quality NC Processing self-lubricating MC nylon POM industrial wear-resistant transmission gearing plastic gear rack?

Good quality CNC Processing self-lubricating MC nylon POM industrial wear-resistant transmission gearing plastic gear rack offers several benefits over traditional equipment, including:

a. Improved accuracy and precision: With a good-quality gear rack, parts can be produced with very tight tolerances, resulting in improved accuracy and precision.

b. Reduced friction and wear: The good quality material used in the gear rack reduces friction and wear, prolonging the lifespan of the machine and reducing maintenance costs.

c. Increased productivity: A well-designed gear rack can improve productivity by allowing workers to work more efficiently and without interruption due to power outages or other issues.

d. Cost savings: By reducing maintenance costs and improving productivity, a good quality gear rack can help companies save money over time.

e. Better ergonomics: A well-designed gear rack can improve ergonomics, making it easier for workers to operate and maintain the machinery.

3. What is the difference between a Gear Rack and a Gear Assembly Line?

A Gear Rack is a component of a Gear Assembly Line that holds and guides gears together while they are being assembled. It is typically made from plastic and is designed to hold multiple gears at once. On the other hand, a Gear Assembly Line is a set of tools and equipment used to assemble a specific type of product, such as a motor or transmission gear.

4. How do I choose the right type of Gear Rack for my needs?

When choosing a Gear Rack, it’s important to consider factors such as the type of gears you need to hold, the number of gears you’ll be working on, the size and weight of your machines, and the materials you’ll be working with. Additionally, it’s recommended to test the gear rack thoroughly before installing it to ensure it meets all safety and performance standards.

5. Are there any additional benefits to using a good quality Gear Rack?

In addition to the benefits listed above, using a good quality Gear Rack can also provide additional benefits such as:

a. Improved reliability: A well-designed gear rack is often built with durable materials and features, which can improve the reliability of the machine and reduce the risk of breakdowns.

b. Reduced downtime: A well-designed gear rack can help prevent delays and disruptions in production by ensuring that the gears are always properly aligned and functioning correctly.

c. Lower maintenance costs: By reducing the risk of breakdowns and preventing damage to the gears, a good quality Gear Rack can help lower maintenance costs over time.

Overall, using a good quality Gear Rack can offer a number of benefits to both manufacturers and end-users, improving accuracy, productivity, and overall efficiency in the production process.

(Good quality cnc processing self lubricating MC nylon POM industrial wear resistant transmission gearbox plastic gear rack)

REQUEST A QUOTE

RELATED PRODUCTS

High quality metal and nylon gear rack for sliding gate

Factory Custom Quality Assurance Smooth Transmission Plastic Gear PP PEEK POM Nylon Gear With High Precision

Existing goods high quality C45 steel spur gear racks M1 10*10*500

HXMT Of China Custom Cnc Machine Parts Custom Plastic Stainless Steel Copper Brass Bevel Gear Spur Pinion Gears

Aloma Factory Custom High Quality Fiberglass Diving Fins Freestyle Training Long Fins Snorkeling Gear