PRODUCT PARAMETERS

Description

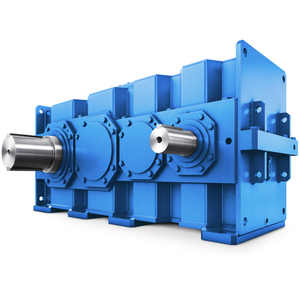

Overview of Precision Custom Made Gear Machining Cnc Turning Cnc 4 Axis Milling Anodized Aluminum Cnc Machining

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of Precision Custom Made Gear Machining Cnc Turning Cnc 4 Axis Milling Anodized Aluminum Cnc Machining

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: Precision Custom Made Gear Machining Cnc Turning Cnc 4 Axis Milling Anodized Aluminum Cnc Machiningsystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern Precision Custom Made Gear Machining Cnc Turning Cnc 4 Axis Milling Anodized Aluminum Cnc Machiningmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(Precision Custom Made Gear Machining Cnc Turning Cnc 4 Axis Milling Anodized Aluminum Cnc Machining)

Specifications of Precision Custom Made Gear Machining Cnc Turning Cnc 4 Axis Milling Anodized Aluminum Cnc Machining

Precision Custom Made Gear Machining with Four-axis Milling, Anodized Aluminum CNC Machining

Product Description: Precision Custom Made Gear Machining is a high-end manufacturing process that utilizes advanced technology to create customized gears and machinery components. Our four-axis milling machines provide a reliable and precise means of machining complex parts in a timely manner.

Anodized aluminum is a popular material choice for gear manufacturing due to its strength, corrosion resistance, and heat conductivity. The use of anodized aluminum not only enhances the appearance of the final product but also improves its durability and longevity.

Our CNC machining capabilities allow us to produce intricate and complex gears with ease, even when working with large or challenging parts. The use of specialized software and equipment allows us to accurately measure and control every detail of the manufacturing process, ensuring consistency and precision throughout the production cycle.

In addition to providing top-quality gear manufacturing services, our company also offers comprehensive after-sales support. We offer fast and efficient repair and maintenance services to ensure that your gear machinery continues to function at its best. Our knowledgeable team of experts can help you identify and resolve any issues that may arise during the production process, helping to maintain your investment and maximizing productivity.

In conclusion, Precision Custom Made Gear Machining is a highly skilled and innovative manufacturing company that provides exceptional service and quality products. With our four-axis milling machines, custom anodized aluminum CNC machinings, and comprehensive after-sales support, we are well-equipped to meet the needs of businesses and organizations across a wide range of industries. Contact us today to learn more about how we can help you achieve your manufacturing goals.

(Precision Custom Made Gear Machining Cnc Turning Cnc 4 Axis Milling Anodized Aluminum Cnc Machining)

Applications of Precision Custom Made Gear Machining Cnc Turning Cnc 4 Axis Milling Anodized Aluminum Cnc Machining

Precision Custom Made Gear Machining CNC Turning CNC 4 Axis Milling Anodized Aluminum CNC Machining: The Future of Manufacturing

As the world becomes increasingly dependent on technology, the need for specialized tools and equipment is increasing. One such tool is precision custom made gear machining. This process involves creating intricate shapes using high-tech machinery, with the goal of producing products that meet exact specifications and provide optimal performance.

One of the primary benefits of precision custom made gear machining is its ability to produce highly complex parts with unparalleled accuracy. Unlike traditional machining methods, which rely on manual tools and techniques, precision custom made gear machining uses computer-controlled machines that can make incredibly precise cuts in a variety of materials.

Another advantage of this process is its ability to produce parts that meet strict tolerances. By using advanced software and machine design software, manufacturers can create designs that are both simple and effective, while also ensuring that they meet all relevant safety standards.

Anodizing aluminum is another popular material used in precision custom made gear machining. This process involves treating aluminum surfaces with anodic layers, which can increase their strength, corrosion resistance, and thermal conductivity. Anodized aluminum can be used to create a wide range of parts, from simple gears to complex aerospace components.

The use of 4-axis milling technology in precision custom made gear machining allows manufacturers to complete intricate tasks quickly and efficiently. With multiple axes moving simultaneously, this technology enables precise control over the movement of each part, resulting in higher-quality products at faster speeds.

In conclusion, precision custom made gear machining offers a range of benefits over traditional manufacturing methods. From its ability to produce highly complex parts with unparalleled accuracy to its ability to produce parts that meet strict tolerances, this technology has become an essential tool for modern manufacturing. As technology continues to evolve, it is likely that precision custom made gear machining will play an even more important role in our economy.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Precision Custom Made Gear Machining Cnc Turning Cnc 4 Axis Milling Anodized Aluminum Cnc Machining

1. What is precision custom made gear machining?

Precision custom made gear machining refers to the process of manufacturing high-quality gears using specialized equipment and techniques. It involves working with complex, customized designs that require intricate measurements and precise adjustments to ensure optimal performance.

2. How does it differ from traditional CNC turning?

CNC turning is a process used to turn metal components by using computer-controlled machinery. While CNC turning can produce parts with good accuracy, precision custom made gear machining goes further by providing more intricate, specialized designs that cannot be achieved with traditional CNC turning alone.

3. Are there any other benefits of precision custom made gear machining?

Yes, there are several advantages to precision custom made gear machining over traditional CNC turning:

– Improved efficiency: Precision custom made gear machining allows for greater speed and precision, which can result in faster production times and lower costs.

– Reduced defects: By using specialized tools and techniques, precision custom made gear machining can help reduce defects in the final product, ensuring that it meets customer expectations.

– Increased quality: Precision custom made gear machining can produce±0.01mm, which means that it can produce products that are stronger, smoother, and more durable than those produced by traditional CNC turning.

4. Who is best suited for precision custom made gear machining?

If you require high-quality that are tailored to specific specifications or requirements, then precision custom made gear machining is the perfect solution. It requires expertise in design, engineering, and to ensure that the resulting meet the highest standards of quality and performance.

5. What materials can be used for precision custom made gear machining?

Precision custom made gear machining can be used to manufacture out of a wide range of materials, including aluminum, titanium, steel, stainless steel, carbon fiber, and others. The choice of material will depend on the desired properties and performance characteristics of the.

(Precision Custom Made Gear Machining Cnc Turning Cnc 4 Axis Milling Anodized Aluminum Cnc Machining)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Custom Cement Mixer Rotating Custom Segment Ring Gear Large Half Ring Gear Custom Segment Ring Gear

TQG Direct s VRB Series Economic Type High Precision High Torque Bevel Planetary Gear Box

Shenzhen HXMT FactoryGear Coupling Nylon Smooth Flat Nylon Gear Bearing Wheel Nylon Double Spur Gears

Custom Brass Gear Watch Dial Cnc Machining Kitchen Part

MAR series low backlash and high precision helical gear reducer 60/90/115/142/180 low clearance stepping planetary servo gearbox