PRODUCT PARAMETERS

Description

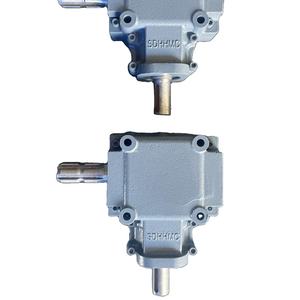

Overview of High Precision Gear Rack Alloy Steel High Quality Material Gear Rack CNC Machine Tool Industrial Equipment Gear Rack

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of High Precision Gear Rack Alloy Steel High Quality Material Gear Rack CNC Machine Tool Industrial Equipment Gear Rack

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: High Precision Gear Rack Alloy Steel High Quality Material Gear Rack CNC Machine Tool Industrial Equipment Gear Racksystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern High Precision Gear Rack Alloy Steel High Quality Material Gear Rack CNC Machine Tool Industrial Equipment Gear Rackmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(High Precision Gear Rack Alloy Steel High Quality Material Gear Rack CNC Machine Tool Industrial Equipment Gear Rack)

Specifications of High Precision Gear Rack Alloy Steel High Quality Material Gear Rack CNC Machine Tool Industrial Equipment Gear Rack

High precision gear rack is an industrial equipment that is widely used in various industries for the efficient and secure storage and movement of gears. This type of gear rack is designed with high-quality materials to ensure durability and reliability.

One of the most critical specifications of a high-precision gear rack is its material composition. The gear rack is made from high-quality alloy steel, which offers excellent strength, corrosion resistance, and heat resistance. It is also lightweight, making it easy to handle and move around.

The accuracy of a high-precision gear rack is also crucial. The gear rack is designed to be highly accurate, ensuring that each gear is placed perfectly on its designated slot. This level of accuracy is essential for precise manufacturing processes, such as manufacturing engine components or machine tools.

Another important specification of a high-precision gear rack is its size and capacity. The gear rack can accommodate a wide range of gears, including those with different diameters and shapes. The rack’s dimensions and capacity allow for maximum flexibility in organizing gears and reducing downtime during production processes.

In addition to these specifications, a high-precision gear rack must also have good safety features. It should have mechanisms in place to prevent gear damage during transportation and handling. The rack should also be equipped with appropriate safety guards to protect workers from accidents.

Overall, a high-precision gear rack is a valuable industrial piece of equipment that plays a critical role in maintaining the efficiency and productivity of manufacturing processes. Its high-quality material composition, accuracy, size, capacity, safety features, and safety guards make it a reliable choice for businesses looking to optimize their production processes.

(High Precision Gear Rack Alloy Steel High Quality Material Gear Rack CNC Machine Tool Industrial Equipment Gear Rack)

Applications of High Precision Gear Rack Alloy Steel High Quality Material Gear Rack CNC Machine Tool Industrial Equipment Gear Rack

High precision gear rack alloy steel high quality material gears rack CNC machine tool industrial equipment gear rack is a versatile and efficient solution for a wide range of applications in manufacturing industry. The product is made from durable and reliable alloy steel, ensuring its ability to withstand heavy loads and operate consistently over time.

One of the key benefits of this type of gear rack is its superior strength-to-weight ratio. The use of alloy steel allows for a significant increase in strength while maintaining a lighter weight, making it an ideal choice for applications that require both durability and portability.

The CNC machine tool used in this product also plays a crucial role in ensuring the accuracy and precision of the gear rack. By using advanced technology such as computer-aided design (CAD) and machine learning algorithms, manufacturers can create gear racks with precise measurements and alignment, resulting in increased efficiency and reduced errors.

In addition, the gear rack is designed to be suitable for various types of industrial equipment, including those used in heavy machinery, robotics, and automotive industries. This makes it an essential component of modern manufacturing processes, enabling companies to produce high-quality products more quickly and efficiently.

Overall, high precision gear rack alloy steel high quality material gears rack CNC machine tool industrial equipment gear rack offers a wide range of benefits for manufacturers looking to improve their productivity and reduce costs. Its durability, reliability, and compatibility make it an essential tool in modern manufacturing processes.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of High Precision Gear Rack Alloy Steel High Quality Material Gear Rack CNC Machine Tool Industrial Equipment Gear Rack

1. What is the difference between a gear rack and a tool chest?

A gear rack is designed to hold and protect gears, while a tool chest is typically used for storing tools such as hammers, screwdrivers, and pliers.

2. What materials can be used for a high precision gear rack?

Alloy steel is one of the most popular materials used in building high precision gear racks due to its strength, durability, and resistance to corrosion. Other materials that may be used include stainless steel, aluminum, or carbon fiber.

3. How do I choose the right size for my gear rack?

The size of your gear rack will depend on the type of equipment you plan to store in it. For example, if you have a lot of heavy machinery, you may want to opt for a larger gear rack with more storage space. If you have lighter equipment, you may want to consider a smaller rack that is more efficient.

4. Are there any additional features I should consider when choosing a gear rack?

When selecting a gear rack, you may also want to consider features such as casters, brakes, and safety locks. These features can help ensure that your gear rack stays secure and that your equipment is protected from damage.

5. Can a gear rack be customized to meet specific needs?

Yes, many gear racks can be customized to meet specific needs. This may involve adding or removing components, changing the shape of the rack, or modifying the internal design to improve efficiency. Contact a supplier or manufacturer to learn more about customization options.

(High Precision Gear Rack Alloy Steel High Quality Material Gear Rack CNC Machine Tool Industrial Equipment Gear Rack)

REQUEST A QUOTE

RELATED PRODUCTS

Hastelloy B-2 C276 C-22 Monel K500 Customized Open Die Forging Gear Ring Gear Ring for Excavator Rotary Table Application

Cnc Customized Brass Worm Gear High Quality Transmission Worm Wheel Gear For Motor Reducer

TILI New Type Mini Excavator Track Drive Motor Hydraulic Motor With Worm Drive Gearbox Patgent Gearbox For Concrete Mixer

Second gear with light selector power switch rotary selector switch

Cnc Machining Oem Factory Plastic Injection Products Plastic Nylon Gear Rack Non-Standard Accessories