PRODUCT PARAMETERS

Description

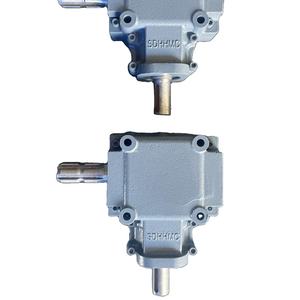

Overview of High Quality Custom Large Mining Gears Customized Procurement New OEM Large Gears

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of High Quality Custom Large Mining Gears Customized Procurement New OEM Large Gears

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: High Quality Custom Large Mining Gears Customized Procurement New OEM Large Gearssystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern High Quality Custom Large Mining Gears Customized Procurement New OEM Large Gearsmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(High Quality Custom Large Mining Gears Customized Procurement New OEM Large Gears)

Specifications of High Quality Custom Large Mining Gears Customized Procurement New OEM Large Gears

High-quality custom large mining gears are engineered to meet the demanding requirements of heavy-duty mining operations. These gears are designed for durability, precision, and reliability, ensuring optimal performance in the most challenging environments. Customized procurement options allow for tailored solutions to meet specific operational needs, while OEM (Original Equipment Manufacturer) standards guarantee compatibility and seamless integration with existing machinery.

The specifications of these large mining gears include the use of premium-grade materials such as alloy steels, which are heat-treated to enhance strength, wear resistance, and fatigue life. Advanced manufacturing techniques, including CNC machining and precision grinding, ensure tight tolerances and superior surface finishes. The gears are available in a wide range of sizes, with diameters ranging from a few meters to over 10 meters, and can handle torque loads exceeding several million Newton-meters.

Customization options include specific tooth profiles, such as spur, helical, or double helical designs, to optimize load distribution and minimize noise and vibration. Surface treatments like carburizing, nitriding, or coating with anti-corrosion materials further enhance performance and longevity. These gears are designed to operate under extreme conditions, including high temperatures, heavy loads, and abrasive environments, making them ideal for applications in open-pit and underground mining.

OEM large gears are manufactured to exacting standards, ensuring compatibility with leading mining equipment brands. The procurement process is streamlined to provide end-to-end solutions, from design and engineering to production, testing, and delivery. Rigorous quality control measures, including non-destructive testing (NDT) and dimensional inspections, ensure that each gear meets or exceeds industry standards.

Whether for new installations or replacement parts, these custom large mining gears offer unmatched performance, reliability, and longevity. With a focus on precision engineering and customer-specific requirements, they are the ideal choice for mining operations seeking to maximize productivity and minimize downtime.

(High Quality Custom Large Mining Gears Customized Procurement New OEM Large Gears)

Applications of High Quality Custom Large Mining Gears Customized Procurement New OEM Large Gears

High-quality custom large mining gears are essential components in the heavy-duty machinery used in the mining industry. These gears are designed to withstand extreme conditions, including high loads, abrasive environments, and continuous operation, making them critical for the efficient and reliable performance of mining equipment. Customized procurement of these gears ensures that they meet the specific requirements of each mining operation, including size, material, and performance specifications. This tailored approach allows for optimal compatibility with existing machinery, reducing downtime and enhancing productivity.

The applications of these large mining gears are vast, ranging from conveyor systems and crushers to ball mills and draglines. In conveyor systems, large gears are used to drive the belts that transport mined materials over long distances, ensuring smooth and efficient operations. In crushers, they play a pivotal role in breaking down large rocks into smaller, manageable pieces, which is a crucial step in the mineral extraction process. Ball mills, which are used for grinding and blending materials, rely on high-quality gears to maintain consistent rotational speeds and achieve the desired particle size. Similarly, draglines, which are massive excavating machines, depend on robust gears to handle the immense loads and stresses involved in moving large volumes of earth and rock.

Custom OEM large gears are manufactured using advanced engineering techniques and high-grade materials, such as alloy steels, to ensure durability and longevity. The customization process involves precise design, rigorous testing, and quality control to meet the exacting standards of the mining industry. By partnering with experienced manufacturers, mining companies can procure gears that are not only tailored to their specific needs but also engineered to deliver superior performance under the most demanding conditions. This results in reduced maintenance costs, extended equipment lifespan, and improved operational efficiency, making custom large mining gears a valuable investment for any mining operation.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of High Quality Custom Large Mining Gears Customized Procurement New OEM Large Gears

When it comes to high-quality custom large mining gears, businesses often have questions about procurement, customization, and OEM services. Here are five frequently asked questions (FAQs) to help you understand the process and benefits of working with a trusted manufacturer for your large gear needs:

1. **What makes custom large mining gears high-quality?**

High-quality custom mining gears are manufactured using premium-grade materials, such as alloy steels, and undergo advanced heat treatment processes to ensure durability and resistance to wear. Precision engineering and strict quality control measures, including rigorous testing for load capacity and performance, guarantee that the gears can withstand the demanding conditions of mining operations.

2. **Can I customize large mining gears to fit my specific requirements?**

Yes, customization is a key feature of high-quality large mining gears. Manufacturers work closely with clients to design gears tailored to specific operational needs, including size, tooth profile, load capacity, and material specifications. Customization ensures optimal performance and longevity in your mining applications.

3. **What is the procurement process for custom large mining gears?**

The procurement process typically begins with a consultation to understand your requirements. Once the design is finalized, the manufacturer provides a detailed quote and timeline. After approval, production begins, followed by quality inspections and delivery. Many manufacturers offer end-to-end support, from design to installation.

4. **Do manufacturers offer OEM services for large mining gears?**

Yes, many manufacturers provide OEM (Original Equipment Manufacturer) services, allowing you to brand the gears as your own. This is ideal for businesses looking to integrate custom gears into their product lines while maintaining their brand identity.

5. **How do I ensure the gears meet industry standards?**

Reputable manufacturers adhere to international standards, such as ISO, AGMA, and DIN, ensuring that the gears meet or exceed industry requirements. Always verify the manufacturer’s certifications and request documentation to confirm compliance with relevant standards.

Investing in high-quality custom large mining gears ensures reliability, efficiency, and cost-effectiveness for your mining operations. Partnering with an experienced manufacturer guarantees tailored solutions that meet your unique needs.

(High Quality Custom Large Mining Gears Customized Procurement New OEM Large Gears)

REQUEST A QUOTE

RELATED PRODUCTS

Custom Heavy Excavator Gearbox Main Drive Helical Large Pinion Wheel Shaft Forging Steel Large Gear And Shaft Assembly

Custom High Performance Casting Auto Transmission Gear From

4812035018 ,4607162182,4812027192 DRIVE GEAR FOR DYNAPAC PAVER F2500CS F2530

Factory Direct High Quality Cheap Standard Custom DIN ISO ANSI Steel Roller Chain Sprocket gear

JM JK JKL JKD gear reducer driving winch for hoisting pull and unloading tow the weight drop