PRODUCT PARAMETERS

Description

Overview of Custom MOD. 1.0 1.5 2 2.5 3 4 5 Drive Big Helical Gear Spur Pinion Gear Wheel Herringbone Gear

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of Custom MOD. 1.0 1.5 2 2.5 3 4 5 Drive Big Helical Gear Spur Pinion Gear Wheel Herringbone Gear

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: Custom MOD. 1.0 1.5 2 2.5 3 4 5 Drive Big Helical Gear Spur Pinion Gear Wheel Herringbone Gearsystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern Custom MOD. 1.0 1.5 2 2.5 3 4 5 Drive Big Helical Gear Spur Pinion Gear Wheel Herringbone Gearmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(Custom MOD. 1.0 1.5 2 2.5 3 4 5 Drive Big Helical Gear Spur Pinion Gear Wheel Herringbone Gear)

Specifications of Custom MOD. 1.0 1.5 2 2.5 3 4 5 Drive Big Helical Gear Spur Pinion Gear Wheel Herringbone Gear

Customized MOD 1.0, 1.5, 2, 2.5, 3, 4, and 5 Drive Gears– including Big Helical, Stimulate Pinion, and Herringbone Gear Wheels– are precision-engineered for longevity and performance throughout commercial applications. Each gear kind is available in steel, alloy steel, or stainless-steel, with personalized teeth profiles, surface area therapies, and birthed sizes. Below are requirements for every variant:

** Big Helical Gears ** feature angled teeth for smooth, peaceful operation in high-speed systems. MOD 1.0 supports 20– 100 teeth, pitch diameters of 20– 100 mm, and tons up to 200 Nm. MOD 1.5 takes care of 15– 75 teeth, 22.5– 112.5 mm sizes, and 300 Nm. MOD 2.0: 10– 50 teeth, 20– 100 mm, 400 Nm. MOD 2.5: 8– 40 teeth, 20– 100 mm, 500 Nm. MOD 3.0: 7– 35 teeth, 21– 105 mm, 600 Nm. MOD 4.0: 5– 25 teeth, 20– 100 mm, 800 Nm. MOD 5.0: 4– 20 teeth, 20– 100 mm, 1000 Nm. Pressure angle: 20 °. Applications: automobile transmissions, commercial equipment.

** Stimulate Pinion Gears ** provide simplicity and effectiveness for low-speed, high-torque systems. MOD 1.0: 10– 50 teeth, 10– 50 mm size, 150 Nm. MOD 1.5: 7– 35 teeth, 10.5– 52.5 mm, 225 Nm. MOD 2.0: 5– 25 teeth, 10– 50 mm, 300 Nm. MOD 2.5: 4– 20 teeth, 10– 50 mm, 375 Nm. MOD 3.0: 3– 15 teeth, 9– 45 mm, 450 Nm. MOD 4.0: 2– 10 teeth, 8– 40 mm, 600 Nm. MOD 5.0: 2– 8 teeth, 10– 40 mm, 750 Nm. Pressure angle: 20 °. Applications: robotics, conveyor systems, clock mechanisms.

** Herringbone Gears ** combine double helical angles for zero axial thrust and high lots capability. MOD 1.0: 25– 120 teeth, 25– 120 mm diameter, 300 Nm. MOD 1.5: 17– 80 teeth, 25.5– 120 mm, 450 Nm. MOD 2.0: 12– 60 teeth, 24– 120 mm, 600 Nm. MOD 2.5: 10– 48 teeth, 25– 120 mm, 750 Nm. MOD 3.0: 8– 40 teeth, 24– 120 mm, 900 Nm. MOD 4.0: 6– 30 teeth, 24– 120 mm, 1200 Nm. MOD 5.0: 5– 24 teeth, 25– 120 mm, 1500 Nm. Stress angle: 20 ° or 25 °. Applications: heavy equipment, marine propulsion, mining tools.

All gears support personalized heat treatments (e.g., carburizing, nitriding), finishes (anti-wear, corrosion-resistant), and bore arrangements. Engineered for integrity, these equipments guarantee optimal power transmission sought after environments. Call for tailored options based on torque, speed, and ecological demands.

(Custom MOD. 1.0 1.5 2 2.5 3 4 5 Drive Big Helical Gear Spur Pinion Gear Wheel Herringbone Gear)

Applications of Custom MOD. 1.0 1.5 2 2.5 3 4 5 Drive Big Helical Gear Spur Pinion Gear Wheel Herringbone Gear

Customized MOD gears, consisting of MOD 1.0, 1.5, 2, 2.5, 3, 4, and 5, are precision-engineered components created for a wide range of industrial applications. These gears are readily available in different arrangements such as helical, stimulate, pinion, herringbone, and gear wheel designs, each tailored to meet certain mechanical requirements. Their modularity and versatility make them crucial in sectors requiring high torque transmission, smooth operation, and toughness.

** MOD 1.0– 2.5 Gears ** are ideal for applications requiring compact layout and moderate load ability. MOD 1.0 and 1.5 equipments, with better teeth, are typically used in robotics, medical tools, and precision instruments where peaceful procedure and minimal vibration are essential. MOD 2 and 2.5 gears strike a balance in between size and stamina, making them suitable for auto transmissions, conveyor systems, and small equipment. Helical equipments in this array excel in decreasing sound, while spur gears offer simpleness and cost-efficiency.

** MOD 3– 5 Gears ** are developed for heavy-duty applications. MOD 3 and 4 equipments deal with greater torque loads, making them perfect for commercial machinery, farming equipment, and building devices. Herringbone equipments in this range eliminate axial thrust, making sure stability in high-stress environments like mining crushers or ship propulsion systems. MOD 5 gears, with their large tooth accounts, are utilized in extreme-load scenarios such as wind generator yaw drives, steel rolling mills, and railway grip systems.

** Stimulate and helical gears ** are extensively made use of in vehicle differentials, transmissions, and power tools because of their efficiency and ease of production. ** Pinion equipments ** pair with shelfs for linear activity in steering systems and CNC makers. ** Herringbone equipments ** are crucial in industries requiring bidirectional tons handling without reaction, such as hydroelectric generators.

Personalized MOD equipments are crafted from materials like set steel, cast iron, or compounds, making sure wear resistance and durability. Their applications cover aerospace, renewable resource, marine, and manufacturing fields. By enhancing tooth profiles and positioning, these equipments reduce power loss and improve operational efficiency. Whether for high-speed automation or sturdy commercial environments, Customized MOD equipments deliver reliability, accuracy, and efficiency, tailored to meet the exact needs of contemporary engineering difficulties.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Custom MOD. 1.0 1.5 2 2.5 3 4 5 Drive Big Helical Gear Spur Pinion Gear Wheel Herringbone Gear

**What is MOD in gear specifications, and how does it affect performance?** MOD (Module) is a metric unit defining gear tooth size, calculated as pitch diameter divided by the number of teeth. MOD 1.0 to 5.0 gears vary in strength and load capacity—higher MOD (e.g., 4.0 or 5.0) suits heavy-duty applications with large torque, while lower MOD (1.0–2.5) works for precision, high-speed systems. Selecting the right MOD ensures optimal power transmission, durability, and noise control.

**What materials are available for custom gears like helical, spur, or herringbone?** Common materials include carbon steel, stainless steel, brass, cast iron, and engineering plastics (e.g., nylon). Steel offers high strength for industrial machinery, while brass and nylon reduce noise in light-duty or food-grade applications. Material choice depends on load, environment (corrosion resistance), thermal stability, and operational noise requirements.

**How do I customize MOD gears for my application?** Provide key specs: MOD size (1.0–5.0), number of teeth, pressure angle (typically 20°), helix angle (for helical/herringbone), gear width, and bore size. Specify application details like torque, RPM, operating temperature, and mounting constraints. Customization ensures compatibility with your system’s load, speed, and environmental conditions.

**What’s the difference between spur, helical, and herringbone gears?** Spur gears have straight teeth for simple, cost-effective solutions but generate noise under load. Helical gears use angled teeth for smoother, quieter operation but require thrust bearings due to axial forces. Herringbone gears (double helical) eliminate axial thrust, offering high torque capacity and durability, ideal for heavy machinery like turbines or mining equipment.

**What is the lead time and pricing for custom MOD gears?** Lead time ranges from 2–6 weeks, depending on design complexity, material availability, and order quantity. Pricing varies by material type, gear size (e.g., MOD 5.0 costs more than MOD 1.0), precision tolerances, and surface treatments (heat treatment, coatings). Bulk orders typically reduce unit costs, though minimum order quantities (MOQs) may apply for specialized materials or large gears.

(Custom MOD. 1.0 1.5 2 2.5 3 4 5 Drive Big Helical Gear Spur Pinion Gear Wheel Herringbone Gear)

REQUEST A QUOTE

RELATED PRODUCTS

High Precision Gear Rack Alloy Steel High Quality Material Gear Rack CNC Machine Tool Industrial Equipment Gear Rack

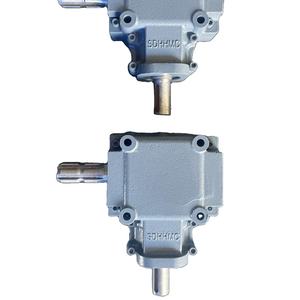

TQG NMRV Series 90W Ratio 1:7.5-1:100 Worm Reducer Gearbox With High Torque Reductor

High Precision Customized Construction Machinery Metal Gear

geared motors gearbox reducer drive power transmission shaft gearbox Helical Worm Gear Reducer Motor

China whole pinion gear differential ring CNC machining parts differential ring and pinion gears