PRODUCT PARAMETERS

Description

Overview of Factory Customized Module 0.2 0.5 0.8 1 1.25 1.5 1.75 2 2.25 Small Steel Spur Gear

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of Factory Customized Module 0.2 0.5 0.8 1 1.25 1.5 1.75 2 2.25 Small Steel Spur Gear

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: Factory Customized Module 0.2 0.5 0.8 1 1.25 1.5 1.75 2 2.25 Small Steel Spur Gearsystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern Factory Customized Module 0.2 0.5 0.8 1 1.25 1.5 1.75 2 2.25 Small Steel Spur Gearmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(Factory Customized Module 0.2 0.5 0.8 1 1.25 1.5 1.75 2 2.25 Small Steel Spur Gear)

Specifications of Factory Customized Module 0.2 0.5 0.8 1 1.25 1.5 1.75 2 2.25 Small Steel Spur Gear

The Manufacturing Facility Personalized Component 0.2, 0.5, 0.8, 1, 1.25, 1.5, 1.75, 2, 2.25 Small Steel Spur Gear is crafted for precision, longevity, and flexibility in diverse mechanical applications. These spur equipments are developed to transmit movement and power efficiently between parallel shafts, ideal for small equipment, robotics, automotive systems, and industrial equipment. Customization alternatives make certain compatibility with specific operational requirements.

** Product & Building And Construction **: Manufactured from top notch steel, these gears use phenomenal strength, put on resistance, and durability. Typical material qualities include carbon steel (e.g., 1045, 4140) for high-load applications and stainless steel (e.g., 304, 316) for deterioration resistance. Heat therapy processes like carburizing, relieving, and solidifying improve surface area hardness (50– 60 HRC) and core sturdiness. Surface area coatings such as black oxide, zinc plating, or nickel covering are offered to minimize rubbing and protect against corrosion.

** Component Array & Specifications **: The component range (0.2– 2.25) suits differing torque and rate needs. Smaller modules (0.2– 0.8) match high-precision, low-load applications, while bigger modules (1.5– 2.25) take care of heavier loads. Customizable parameters consist of teeth matter (10– 150+), bore size (2– 50 mm), face size (1– 20 mm), and stress angle (commonly 20 °). Equipments are CNC-machined to make certain tight tolerances (ISO 1328 or AGMA standards) for smooth meshing and very little noise.

** Performance & Applications **: These equipments operate effectively under high rotational rates and moderate-to-high torque conditions. They work with temperature levels ranging from -30 ° C to 120 ° C, relying on material and therapy. Applications include servo electric motors, clock mechanisms, clinical gadgets, conveyor systems, and vehicle transmissions.

** Customization & Quality Control **: Customers can specify exact dimensions, tooth profiles (involute), and installing arrangements. Prototyping and batch production are sustained, with extensive top quality look for dimensional accuracy, hardness, and surface area honesty. Optional laser engraving or component numbering aids in inventory management.

** Key Technical Specifications **:.

– Component: 0.2, 0.5, 0.8, 1, 1.25, 1.5, 1.75, 2, 2.25.

– Product: Carbon steel, alloy steel, stainless steel.

– Teeth: 10– 150+ (adjustable).

– Bore Size: 2– 50 mm (keyway or established screw options).

– Face Size: 1– 20 mm.

– Pressure Angle: 14.5 ° or 20 °( standard

).- Surface area Firmness: 50– 60 HRC (heat-treated versions).

– Complete: Black oxide, zinc, nickel, or uncoated.

– Compliance: ISO, AGMA, or customer-specific standards.

Created for reliability in demanding settings, these equipments combine accuracy engineering with flexible personalization to fulfill precise operational demands.

(Factory Customized Module 0.2 0.5 0.8 1 1.25 1.5 1.75 2 2.25 Small Steel Spur Gear)

Applications of Factory Customized Module 0.2 0.5 0.8 1 1.25 1.5 1.75 2 2.25 Small Steel Spur Gear

Factory customized small steel stimulate gears with components varying from 0.2 to 2.25 are precision-engineered parts designed for diverse industrial and mechanical applications. These gears are crafted from high-quality steel, guaranteeing resilience, wear resistance, and reputable performance under varying tons and functional problems. Their small dimension and personalized requirements make them ideal for integration right into systems needing precise motion control, power transmission, and torque management.

In robotics and automation, these equipments are critical for servo motors, robot arms, and conveyor systems, where exact equipment proportions and smooth operation are crucial. The smaller modules (0.2– 0.8) suit micro-robotics and small devices, allowing accurate movements in limited rooms. For automobile applications, components 1– 2.25 are made use of in seat adjusters, windshield wipers, and transmission systems, offering high toughness and noise reduction in compact settings up.

Medical tools, such as imaging gadgets, surgical robotics, and drug distribution systems, depends on sterilizable, corrosion-resistant steel gears (modules 0.5– 1.5) to guarantee accuracy and dependability in sensitive atmospheres. In customer electronics, little spur gears (components 0.2– 1) drive cams, printers, and smart home tools, balancing silent operation with small layout.

Industrial equipment uses bigger components (1.75– 2.25) for durable devices like product packaging machines, CNC devices, and farming machinery, where high torque and load-bearing ability are paramount. Aerospace and protection applications take advantage of these gears for actuators, navigating systems, and drone devices, prioritizing lightweight yet robust performance under extreme problems.

Renewable energy systems, including solar trackers and wind turbine pitch controls, utilize tailored equipments (components 1– 2) to optimize energy performance with precise angular modifications. Enthusiast tasks, such as RC lorries and do it yourself robotics, gain from the adaptability of these gears, allowing fanatics to customize gear trains for speed or power.

Factory customization makes certain gears meet exact specifications– material coverings, tooth profiles, birthed dimensions– improving compatibility with existing systems. Their convenience throughout markets, combined with steel’s strength, makes these spur tailors a foundation of efficient, reliable mechanical options. Whether for high-precision jobs or heavy-load scenarios, these elements provide performance, longevity, and adaptability.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Factory Customized Module 0.2 0.5 0.8 1 1.25 1.5 1.75 2 2.25 Small Steel Spur Gear

**What is a module in spur gears, and why does the size range matter?**

The module (denoted as “m”) refers to the ratio of the pitch diameter to the number of teeth, determining the gear’s size and tooth strength. Our Factory Customized Steel Spur Gears offer modules from 0.2 to 2.25, allowing precise customization for applications requiring compact designs (smaller modules like 0.2) or higher torque transmission (larger modules like 2.25). The range ensures compatibility with diverse mechanical systems, from delicate instruments to industrial machinery.

**Why choose steel for these spur gears?**

Steel provides superior durability, wear resistance, and load-bearing capacity compared to plastic or brass. It’s ideal for high-stress, high-speed, or high-temperature environments. Our gears are heat-treated and precision-machined to enhance hardness and reduce friction, ensuring long-term performance in demanding applications like robotics, automotive systems, or industrial equipment.

**What customization options are available?**

We tailor gears to your specifications, including tooth count, pitch diameter, bore size (with keyways or set screws), face width, and surface treatments (e.g., black oxide, zinc plating). Custom tolerances and coatings can also be applied to meet noise reduction, corrosion resistance, or lubrication needs. Provide your design parameters, and we’ll optimize the gear for your application.

**Are these gears suitable for high-precision applications?**

Yes. Our gears are CNC-machined to ensure tight tolerances (ISO 8-10 standards) and smooth meshing. The module-specific tooth profiles are engineered to minimize backlash and vibration, making them ideal for precision uses like medical devices, aerospace components, or automation systems. Surface finishes and post-machining treatments further enhance accuracy and longevity.

**What is the lead time and minimum order quantity (MOQ)?**

Lead times vary based on design complexity and order volume but typically range from 2–4 weeks. We accommodate both small-batch prototyping (MOQ as low as 10 units) and large-scale production. Bulk orders may qualify for discounted pricing. Contact us with your requirements for a tailored quote and timeline.

(Factory Customized Module 0.2 0.5 0.8 1 1.25 1.5 1.75 2 2.25 Small Steel Spur Gear)

REQUEST A QUOTE

RELATED PRODUCTS

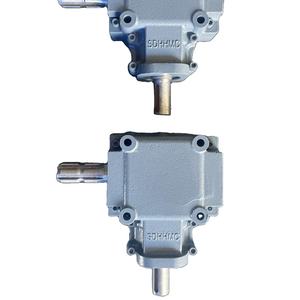

SLDBY Series Series Heavy Duty Helical Gear Reducer Gearbox For Crane

1400RPM Gearbox Transmission Reducer Speed Ratio 1 30 1 60 Rv Series Worm Gear Machinery Farm Industry Models nmrv nrv63 nmrv063

Multipurpose grease Planetary gearbox reduction motor Power tool High temperature Resistant wear Resistant pressure

Aluminum casting customized OEM precision manufacturing high pressure casting gearbox valve plate piston

Genuine K19 K38 K50 NT855 NTA855 VTA28 N14 LT10 M11 QSK19 QSK38 QSK45 QSK60 Crankshaft Gear and Crankshaft For Cummins