PRODUCT PARAMETERS

Description

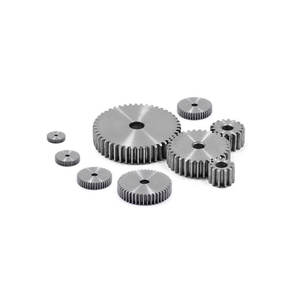

Overview of High Precision Custom 45 Steel Spline Hub Sleeve Parts Power Transmission Spur Gears Helical Gears Bevel Gears

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of High Precision Custom 45 Steel Spline Hub Sleeve Parts Power Transmission Spur Gears Helical Gears Bevel Gears

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: High Precision Custom 45 Steel Spline Hub Sleeve Parts Power Transmission Spur Gears Helical Gears Bevel Gearssystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern High Precision Custom 45 Steel Spline Hub Sleeve Parts Power Transmission Spur Gears Helical Gears Bevel Gearsmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(High Precision Custom 45 Steel Spline Hub Sleeve Parts Power Transmission Spur Gears Helical Gears Bevel Gears)

Specifications of High Precision Custom 45 Steel Spline Hub Sleeve Parts Power Transmission Spur Gears Helical Gears Bevel Gears

High Precision Custom 45 Steel Spline Hub Sleeve Parts and Power Transmission Gears (Spur, Helical, Bevel) are engineered for durability, precision, and smooth power transfer in industrial applications. Made from high-quality 45 carbon steel, these parts go through warmth therapy (quenching and tempering) to accomplish a surface hardness of 45-50 HRC and core sturdiness, making certain resistance to put on, tiredness, and high-stress problems. The spline hub sleeve includes precision-ground inner and external splines with limited tolerances (ISO 2768-fh standards) for smooth engagement, very little backlash, and optimum torque transmission. Personalized spline accounts (involute, straight-sided) fit shaft sizes from 10 mm to 200 mm, with bore tolerances as low as ± 0.01 mm. Surface surfaces range from Ra 0.8 μm to Ra 1.6 μm for decreased friction.

Stimulate equipments are offered in modules (1– 10), pressure angles (20 ° or 25 °), and as much as 200 teeth, supporting torque abilities up to 5000 Nm. Helical equipments include helix angles (15 °– 30 °) for quieter operation, with modules (1– 8) and face widths up to 150 mm. Bevel equipments include straight and spiral configurations, cone angles (5 °– 90 °), and modules (1– 6) for right-angle power transmission at performances exceeding 98%. All gears are CNC-machined to AGMA Q10 accuracy requirements, with tooth profile errors under 0.02 mm.

Applications include automotive drivetrains, hefty equipment, robotics, and renewable energy systems. Personalization alternatives consist of nitriding/carburizing for enhanced surface area firmness (up to 60 HRC), anti-corrosion finishes (zinc, nickel), and alterations to tooth geometry or bore/keyway measurements. Rated for rotational speeds up to 10,000 RPM and operating temperatures from -30 ° C to 200 ° C, these components undergo extensive top quality checks (CMM, torque testing, metallurgical evaluation) to ensure compliance with ISO 9001 and hubbub 5480 criteria. Backed by load-testing certifications, they supply long life span with marginal maintenance. Call for customized remedies in product quality, dimensional specifications, or batch production.

(High Precision Custom 45 Steel Spline Hub Sleeve Parts Power Transmission Spur Gears Helical Gears Bevel Gears)

Applications of High Precision Custom 45 Steel Spline Hub Sleeve Parts Power Transmission Spur Gears Helical Gears Bevel Gears

High precision custom 45 steel spline hub sleeve components are engineered to deliver outstanding performance in power transmission systems, guaranteeing seamless torque transfer, longevity, and reliability throughout varied commercial applications. Crafted from high-quality 45 carbon steel, these elements combine exceptional tensile toughness, wear resistance, and heat-treated solidity, making them suitable for sturdy procedures sought after settings. Their accurate machining guarantees limited tolerances and smooth combination with spur gears, helical gears, and bevel equipments, enhancing efficiency in mechanical systems.

** Stimulate Gears **: These spline center sleeves are important to spur equipment assemblies, where straight power transmission in between identical shafts is required. Typically used in automotive transmissions, conveyor systems, and machinery, the sleeves make sure accurate positioning and minimize reaction, preserving regular call in between equipment teeth for effective power transfer under high-load problems.

** Helical Gears **: In helical gear systems, the angled teeth demand elements that fit continual, smooth involvement. The spline hub sleeves reduce vibration and noise by maintaining uniform load distribution throughout the equipment faces. This makes them optimal for high-speed applications such as generators, pumps, and precision production tools.

** Bevel Gears **: For bevel gears, which transfer power between intersecting shafts at differing angles, these sleeves give critical assistance in applications like differential drives, aerospace systems, and robotics. Their personalized design makes sure ideal meshing of equipment teeth, even under angular stress, improving torque transmission and functional stability.

Personalization enables these spline hub sleeves to satisfy exact specs, including spline profiles, sizes, and surface treatments like nitriding or covering for corrosion resistance. Industries such as automotive, aerospace, renewable energy, and heavy machinery rely on these components for their capacity to hold up against extreme stress, lower upkeep downtime, and prolong life span.

By incorporating robust product residential or commercial properties with accuracy design, 45 steel spline hub sleeves raise the performance of gear-driven systems, making sure integrity, performance, and longevity in power transmission applications worldwide.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of High Precision Custom 45 Steel Spline Hub Sleeve Parts Power Transmission Spur Gears Helical Gears Bevel Gears

**What is 45 steel, and why is it used for spline hub sleeves and gears?**

45 steel is a medium-carbon alloy known for its high strength, durability, and excellent machinability. It’s heat-treatable, allowing for enhanced surface hardness and wear resistance, making it ideal for high-precision spline hub sleeves, spur gears, helical gears, and bevel gears. Its balanced carbon content ensures optimal performance in power transmission systems under heavy loads and high torque, minimizing wear and extending component lifespan.

**What applications are these custom spline hubs and gears suited for?**

These components are engineered for demanding industrial applications, including automotive drivetrains, heavy machinery, robotics, aerospace systems, and renewable energy equipment. They transmit torque efficiently in gearboxes, differential systems, and couplings, ensuring smooth power transfer. Custom spline hubs and helical/bevel gears are also used in precision machinery requiring low noise and vibration, such as CNC machines or conveyor systems.

**What tolerances and precision standards do these parts meet?**

High-precision spline hubs and gears are manufactured to tight tolerances (typically ISO 6-7 grade or AGMA 12-13 standards). Advanced CNC machining, grinding, and honing ensure micron-level accuracy in tooth profiles, pitch, and surface finish (Ra ≤0.8μm). This guarantees seamless meshing with mating components, reducing friction and energy loss while maximizing load-bearing capacity and operational efficiency.

**Can these components be customized for unique requirements?**

Yes, they are fully customizable in terms of spline geometry (involute, straight-sided), module/pitch, pressure angle, helix angle, and bore dimensions. Material alternatives like stainless steel or alloy steels (e.g., 20CrMnTi) are available for corrosion resistance or higher toughness. Custom heat treatments, coatings (nitriding, black oxide), and certifications (ISO, ASTM) can also be specified to meet industry-specific demands.

**How do I maintain spline hubs and gears for longevity?**

Regular lubrication with high-viscosity grease or oil is critical to minimize wear. Inspect for debris, pitting, or misalignment during routine maintenance. Avoid overloading and ensure proper alignment during installation. For harsh environments, opt for corrosion-resistant coatings. Periodic non-destructive testing (e.g., magnetic particle inspection) helps detect subsurface cracks early, preventing unexpected failures in power transmission systems.

(High Precision Custom 45 Steel Spline Hub Sleeve Parts Power Transmission Spur Gears Helical Gears Bevel Gears)

REQUEST A QUOTE

RELATED PRODUCTS

Mine Equipment Spare Parts Large Diameter gear Wheel High Quality Spur Casting Large Gear Wheel

OND manufactures 26 27 28 mm height 2 6 lugs black pom gear rack and pinion lift

4812035018 ,4607162182,4812027192 DRIVE GEAR FOR DYNAPAC PAVER F2500CS F2530

High Quality KUNDI Professional Gear Set Pinion Bevel Gear for power tools spare part 24-230

heavy-duty single two three stage helical bevel cylindrical harden softened gear speed reducer reduction gearbox