PRODUCT PARAMETERS

Description

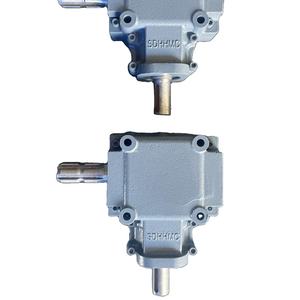

Overview of OEM Customized Stainless Steel Gear Parts CNC Machining With Turned Finish New Condition Custom Services

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of OEM Customized Stainless Steel Gear Parts CNC Machining With Turned Finish New Condition Custom Services

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: OEM Customized Stainless Steel Gear Parts CNC Machining With Turned Finish New Condition Custom Servicessystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern OEM Customized Stainless Steel Gear Parts CNC Machining With Turned Finish New Condition Custom Servicesmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(OEM Customized Stainless Steel Gear Parts CNC Machining With Turned Finish New Condition Custom Services)

Specifications of OEM Customized Stainless Steel Gear Parts CNC Machining With Turned Finish New Condition Custom Services

OEM Personalized Stainless Steel Equipment Components are precision-engineered parts created for sectors calling for high-performance, resilience, and corrosion resistance. These components are produced using advanced CNC machining technology, guaranteeing tight resistances (typically within ± 0.005 mm) and remarkable dimensional accuracy. The material alternatives include premium-grade stainless-steels such as 304, 316, and 17-4 PH, picked for their strength, heat resistance, and viability for severe settings. Modification is readily available in gear kinds (spur, helical, bevel, worm), sizes (diameters from 5 mm to 500 mm), tooth accounts, and birthed setups to fulfill details application requirements.

CNC transforming and crushing procedures are utilized to accomplish a smooth turned coating, with surface roughness (Ra) ranging from 0.8 to 3.2 μm, depending on needs. Post-machining treatments like brightening, passivation, or electropolishing boost surface area quality and deterioration resistance. All components go through strenuous top quality checks, including CMM measurement, solidity testing, and torque testing, to ensure compliance with ISO 9001 standards.

New-condition gear parts are supplied with no previous use, packaged securely to stop damages during transit. Customized solutions consist of prototype advancement, small-batch manufacturing, and high-volume orders, with preparations as short as 5– 7 days for conventional demands. Customers can offer CAD/CAM data or collaborate with engineering teams for style optimization. Additional services consist of warmth treatment (quenching, toughening up), lubrication, and customized branding.

Ideal for auto, aerospace, medical devices, and commercial machinery, these equipments master applications demanding accuracy activity control, load-bearing capacity, and durability. OEM collaborations take advantage of flexible MOQs, competitive prices, and committed technical support. Ecological compliance is guaranteed through RoHS and REACH requirements. Get in touch with for tailored remedies, including material qualifications and DFM analysis, to maximize equipment performance for your one-of-a-kind operational requirements.

(OEM Customized Stainless Steel Gear Parts CNC Machining With Turned Finish New Condition Custom Services)

Applications of OEM Customized Stainless Steel Gear Parts CNC Machining With Turned Finish New Condition Custom Services

OEM customized stainless-steel gear components manufactured through CNC machining with a transformed coating deal accuracy, toughness, and convenience for a vast array of industrial applications. These parts are crafted to meet precise specs, making sure smooth combination right into complicated equipment and systems. Making use of stainless-steel guarantees corrosion resistance, high stamina, and long life, making them ideal for atmospheres exposed to dampness, chemicals, or extreme temperatures. With CNC machining, equipments attain tight tolerances and smooth surface finishes, important for reducing friction, noise, and put on in vibrant operations.

In the automotive sector, these equipments are made use of in transmissions, steering systems, and engine elements, where integrity and performance under anxiety are extremely important. The aerospace sector relies upon them for touchdown gear systems, actuator systems, and generator components, taking advantage of their lightweight yet durable construction. Clinical equipment manufacturers utilize stainless-steel gears in medical tools, imaging gadgets, and robotic medical systems, where accuracy and sterility are non-negotiable.

Industrial automation and robotics rely on personalized gears for accurate motion control in conveyor belts, robot arms, and CNC equipment. The transformed finish enhances surface area honesty, guaranteeing smooth involvement and extended service life. In the marine and offshore sectors, stainless steel gears endure deep sea direct exposure in propulsion systems, winches, and anchor handling equipment. Renewable resource applications, such as wind turbines and solar radar, use these equipments to preserve performance in rough outside problems.

Custom-made solutions permit clients to define equipment measurements, tooth accounts, firmness degrees, and surface treatments like passivation or sprucing up. Whether creating models or high-volume batches, OEM producers ensure consistency and compliance with global requirements. The capacity to tailor gears for unique applications– from small parts in electronics to heavy-duty industrial equipments– makes this solution indispensable for innovation-driven industries. By integrating sophisticated CNC modern technology with stainless steel’s superior homes, services attain optimized efficiency, decreased downtime, and cost-efficient solutions for their mechanical systems.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of OEM Customized Stainless Steel Gear Parts CNC Machining With Turned Finish New Condition Custom Services

1. **What materials are used in OEM customized stainless steel gear parts CNC machining?** We primarily use high-grade stainless steel, such as 304, 316, or 17-4 PH, known for their corrosion resistance, durability, and mechanical strength. These materials are ideal for gears exposed to harsh environments, high loads, or precision applications. Custom material requests are accommodated based on your project’s specific requirements, including heat resistance or enhanced wear properties.

2. **What tolerances and precision levels can be achieved with CNC machining for stainless steel gears?** Our CNC machines deliver tight tolerances of up to ±0.005 mm (±0.0002 inches) for gear parts, ensuring precise tooth profiles, pitch diameters, and surface finishes. Advanced software and quality control processes guarantee consistency, even for complex geometries. The turned finish provides smooth surfaces, reducing friction and improving gear performance in motion-critical applications.

3. **How customizable are the gear parts in terms of design and finish?** We offer full customization, including gear size, tooth profile (spur, helical, bevel), bore dimensions, and surface treatments. Clients can submit CAD files, sketches, or samples for replication. Turned finishes are standard, but additional options like polishing, electroplating, or passivation are available for enhanced aesthetics or corrosion protection.

4. **What is the typical lead time for custom stainless steel gear orders?** Lead times depend on order volume and complexity. Prototypes or small batches ship within 1–2 weeks, while large-scale production may take 3–5 weeks. We prioritize urgent requests and maintain streamlined workflows to minimize delays without compromising quality.

5. **How do you ensure the quality and durability of CNC-machined stainless steel gears?** Each gear undergoes rigorous inspection, including dimensional checks with CMMs, material composition verification, and surface finish analysis. Load testing and performance simulations ensure parts meet operational demands. We adhere to ISO 9001 standards and provide material certifications, ensuring gears perform reliably in industrial, automotive, or aerospace applications. Our team collaborates closely with clients to refine designs and meet exact specifications.

(OEM Customized Stainless Steel Gear Parts CNC Machining With Turned Finish New Condition Custom Services)

REQUEST A QUOTE

RELATED PRODUCTS

Professional Factory Stable Transmission Good Transmission Rate Diesel Engine Gears For The Marine Industry

Martin gear ,Martin Spur gear Module 0.5,0.8,1,1.5,2,etc

OEM Spur Gear Stainless Auto Transmission 35 Tooth 8mm Bore Large Spur Gear Set Parts Double Spur Steel Gears

Innovative Turning Process TCGW110204 TPGW Hard Turning Gear With The Most Cost Efficient Surfaces

High Precision Gear Rack Alloy Steel High Quality Material Gear Rack CNC Machine Tool Industrial Equipment Gear Rack