PRODUCT PARAMETERS

Description

Overview of Dakunlun Custom CNC Internal Rack Pinion Gear Accordig To Drawings Helical Gear Metal Gear

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of Dakunlun Custom CNC Internal Rack Pinion Gear Accordig To Drawings Helical Gear Metal Gear

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: Dakunlun Custom CNC Internal Rack Pinion Gear Accordig To Drawings Helical Gear Metal Gearsystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern Dakunlun Custom CNC Internal Rack Pinion Gear Accordig To Drawings Helical Gear Metal Gearmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(Dakunlun Custom CNC Internal Rack Pinion Gear Accordig To Drawings Helical Gear Metal Gear)

Specifications of Dakunlun Custom CNC Internal Rack Pinion Gear Accordig To Drawings Helical Gear Metal Gear

Dakunlun Custom CNC Internal Rack Pinion Gear (Helical Gear, Metal Gear) is a precision-engineered component designed for high-performance motion control systems. Manufactured to meet exact client specifications, these gears are crafted using advanced CNC machining technology, ensuring accuracy, durability, and seamless integration with existing machinery. The helical design of the gear teeth provides smoother operation, reduced noise, and higher load-bearing capacity compared to traditional spur gears, making them ideal for heavy-duty industrial applications.

**Material Options:** Available in high-strength metals such as 4140/4340 alloy steel, stainless steel (304/316), aluminum, brass, or titanium. Material selection is tailored to application requirements, prioritizing factors like corrosion resistance, wear resistance, and tensile strength. Heat treatment processes (e.g., carburizing, quenching) are applied to enhance surface hardness (up to HRC 58-62) and longevity.

**Key Specifications:**

– **Module Range:** 1 to 10 (customizable as per drawings).

– **Pressure Angle:** 20° standard (14.5°, 25°, or custom angles available).

– **Helix Angle:** Adjustable between 15° to 30° for optimal torque transmission and meshing efficiency.

– **Tooth Profile:** Precision-ground helical teeth with strict adherence to DIN, ISO, or AGMA standards.

– **Dimensional Accuracy:** Tight tolerances (up to ISO 6-8 grade) for pitch, concentricity, and tooth alignment.

– **Surface Finish:** Ra 0.8–1.6 μm post-machining, with optional coatings (e.g., zinc plating, nitriding) for added protection.

**Customization:** The internal rack and pinion system is fully customizable based on client-provided drawings. Modifications include bore size, keyway dimensions, tooth count, pitch diameter, and overall gear geometry. Dakunlun supports both metric and imperial units.

**Applications:** Suited for CNC machinery, robotics, automotive steering systems, packaging equipment, and aerospace actuators. The helical design ensures minimal backlash and high positional accuracy in high-speed or high-torque environments.

**Quality Assurance:** Each gear undergoes rigorous inspection via CMM (Coordinate Measuring Machine) and gear testers to verify profile accuracy, surface integrity, and dimensional compliance. Certifications include ISO 9001 and RoHS compliance.

**Lead Time:** 15–30 days post-design approval, depending on complexity. Prototype services available for design validation.

Dakunlun’s expertise in custom CNC gear manufacturing ensures reliable, high-precision solutions tailored to your mechanical system’s demands. Contact for tailored quotes or technical support.

(Dakunlun Custom CNC Internal Rack Pinion Gear Accordig To Drawings Helical Gear Metal Gear)

Applications of Dakunlun Custom CNC Internal Rack Pinion Gear Accordig To Drawings Helical Gear Metal Gear

Dakunlun Custom CNC Internal Rack Pinion Gear, Helical Gear, and Metal Gear solutions are precision-engineered components designed to meet the exacting demands of modern industrial applications. Manufactured using advanced CNC machining technology, these gears are tailored to customer specifications, ensuring seamless integration into complex systems. Their applications span diverse industries, offering reliability, durability, and high-performance motion control.

In robotics and automation, Dakunlun’s internal rack and pinion gears enable precise linear-to-rotational motion conversion, essential for robotic arms, CNC machinery, and conveyor systems. The helical gear design reduces noise and vibration while improving load distribution, making them ideal for high-speed, high-torque operations in manufacturing plants. Customizable tooth profiles and pressure angles ensure optimal meshing with other components, minimizing wear and enhancing longevity.

The automotive industry benefits from these gears in steering systems, transmission assemblies, and electric vehicle drivetrains. Their metal construction—commonly from hardened steel, stainless steel, or aluminum—provides exceptional strength and resistance to extreme temperatures and corrosive environments. Helical gears, with their angled teeth, deliver smoother engagement and higher efficiency compared to spur gears, improving fuel economy and driving performance.

Aerospace and marine sectors rely on Dakunlun’s custom gears for critical applications like flight control systems, landing gear mechanisms, and ship propulsion. The CNC-machined internal rack and pinion setups ensure tight tolerances and repeatability, meeting stringent safety and precision standards. Custom materials, including titanium alloys, are available for lightweight yet durable solutions in harsh operational conditions.

Heavy machinery and construction equipment utilize these gears for their ability to handle heavy loads and shock resistance. The internal rack design offers compact integration in excavators, cranes, and hydraulic systems, maximizing space efficiency. Dakunlun’s commitment to producing gears according to client drawings ensures compatibility with legacy systems and bespoke engineering requirements.

By combining CNC precision, material versatility, and helical gear advantages, Dakunlun delivers gears that enhance operational efficiency, reduce downtime, and adapt to specialized industrial challenges. Whether for prototyping or mass production, their solutions prioritize quality, performance, and customization, empowering industries to achieve superior mechanical outcomes.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Dakunlun Custom CNC Internal Rack Pinion Gear Accordig To Drawings Helical Gear Metal Gear

What materials are used for Dakunlun Custom CNC Internal Rack Pinion Gears? Dakunlun uses high-quality metals such as carbon steel, stainless steel, alloy steel, and aluminum, depending on application requirements. These materials ensure durability, wear resistance, and optimal performance under high-stress conditions. Custom material choices are available to meet specific hardness, corrosion resistance, or weight needs based on client drawings.

How precise are your custom helical gears? Our CNC machining process guarantees tight tolerances, typically within ISO 1328 or AGMA 2000 standards. Gear profiles, tooth dimensions, and helix angles are manufactured to match client drawings precisely, ensuring smooth meshing, minimal backlash, and efficient power transmission. Advanced metrology tools verify accuracy at every production stage.

Can these gears handle high-load applications? Yes. Dakunlun’s helical rack and pinion gears are engineered for high-load, high-torque environments. The helical design distributes load evenly across multiple teeth, reducing stress and noise. Heat-treated metals further enhance strength and longevity, making them ideal for industrial machinery, automation systems, and heavy equipment.

What is the lead time for custom gear production? Lead times vary based on complexity and order volume but typically range from 2–6 weeks. Prototype services are available for urgent validation. Detailed drawings upfront help streamline production, and our team provides timelines after reviewing design specifications.

What industries are these gears suited for? They are widely used in automation, robotics, automotive, aerospace, CNC machinery, and material handling systems. Their precision, durability, and adaptability make them ideal for applications requiring reliable motion control, such as linear actuators, conveyor systems, and precision positioning equipment. Customization ensures compatibility with niche or specialized industrial needs.

(Dakunlun Custom CNC Internal Rack Pinion Gear Accordig To Drawings Helical Gear Metal Gear)

REQUEST A QUOTE

RELATED PRODUCTS

High quality and durable gear shaping cutter gear cutting durable HSS M-2 gear shaping cutter

Chinese Factory 10T Mechanical skid-resistant gear puller

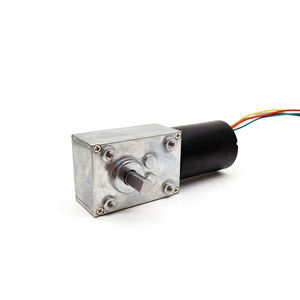

90 Degree Gearbox 200Rpm 58-3650 Right Angle 12V 24V 36V Double Shaft Worm Gear BLDC Motor

Machinery engine parts diesel engine gear housing cnc machining milling turning parts

High Precision Customized Construction Machinery Metal Gear