PRODUCT PARAMETERS

Description

Overview of Custom Brass Gear Watch Dial Cnc Machining Kitchen Part

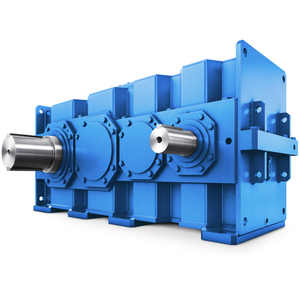

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of Custom Brass Gear Watch Dial Cnc Machining Kitchen Part

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: Custom Brass Gear Watch Dial Cnc Machining Kitchen Partsystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern Custom Brass Gear Watch Dial Cnc Machining Kitchen Partmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(Custom Brass Gear Watch Dial Cnc Machining Kitchen Part)

Specifications of Custom Brass Gear Watch Dial Cnc Machining Kitchen Part

The Custom Brass Gear Watch Dial CNC Machining Kitchen Part is a precision-engineered component designed for both functional and aesthetic applications. Crafted from high-quality brass, this product offers exceptional durability, corrosion resistance, and a polished finish that enhances its visual appeal. The brass material ensures longevity and reliability, making it suitable for intricate designs and demanding environments.

This custom gear watch dial is manufactured using advanced CNC machining technology, ensuring precise dimensions and tight tolerances. The CNC process guarantees consistency and accuracy, making it ideal for applications where precision is critical. The gear design is meticulously crafted to ensure smooth operation and compatibility with various mechanical systems, particularly in watchmaking and decorative kitchen components.

The product is available in custom sizes and configurations to meet specific requirements. Whether used as a functional gear in a watch mechanism or as a decorative element in kitchen hardware, this brass gear dial offers versatility and performance. Its intricate detailing and fine craftsmanship make it a standout piece for both industrial and artistic applications.

The brass material provides excellent machinability, allowing for intricate patterns and designs to be etched or engraved onto the surface. This feature makes it a popular choice for custom projects, where personalization and uniqueness are key. Additionally, the brass gear dial can be further finished with plating or polishing to achieve a desired look, such as a vintage brass patina or a sleek, modern shine.

This product is ideal for watchmakers, designers, and manufacturers seeking high-quality, custom-made components. Its combination of functionality, durability, and aesthetic appeal makes it a valuable addition to any project. Whether used in timepieces, kitchen hardware, or other mechanical systems, the Custom Brass Gear Watch Dial CNC Machining Kitchen Part delivers unmatched precision and style.

(Custom Brass Gear Watch Dial Cnc Machining Kitchen Part)

Applications of Custom Brass Gear Watch Dial Cnc Machining Kitchen Part

Custom brass gear watch dial CNC machining is a highly specialized process that combines precision engineering with artistic craftsmanship to create intricate and functional components. These machined parts are not only essential in the watchmaking industry but also find unique applications in kitchen equipment, where durability, precision, and aesthetics are equally important.

In the world of horology, custom brass gear watch dials are a testament to the fusion of tradition and technology. CNC machining ensures that each gear is crafted with micron-level accuracy, ensuring smooth operation and longevity. The brass material, known for its corrosion resistance and timeless appeal, adds a touch of elegance to the watch dials, making them a favorite among luxury watchmakers. The intricate designs and precise tooth profiles of these gears are achieved through advanced CNC techniques, allowing for customization to meet specific design requirements.

Beyond watchmaking, custom brass CNC-machined parts have found their way into high-end kitchen equipment. In modern kitchens, precision and durability are paramount, especially in appliances like coffee grinders, meat slicers, and mixers. Brass gears and components machined through CNC processes ensure reliable performance, even under high stress and frequent use. The material’s resistance to wear and tear makes it ideal for kitchen applications, where hygiene and longevity are critical. Additionally, the aesthetic appeal of brass adds a touch of sophistication to kitchen gadgets, making them not just functional but also visually appealing.

The versatility of CNC machining allows for the creation of custom parts tailored to specific kitchen equipment, ensuring seamless integration and optimal performance. Whether it’s a finely crafted watch dial or a robust kitchen gear, custom brass CNC machining delivers precision, durability, and elegance, making it a preferred choice for industries that demand the highest standards of quality and craftsmanship.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Custom Brass Gear Watch Dial Cnc Machining Kitchen Part

Custom brass gear watch dial CNC machining kitchen parts are precision-engineered components that combine functionality with aesthetic appeal. Here are five frequently asked questions about these unique products:

1. **What materials are used in custom brass gear watch dial CNC machining kitchen parts?**

These parts are typically crafted from high-quality brass, known for its durability, corrosion resistance, and ability to achieve intricate designs. Brass is also favored for its golden hue, which adds a luxurious touch to both watch dials and kitchen components.

2. **What is the CNC machining process, and why is it used?**

CNC (Computer Numerical Control) machining is a manufacturing process that uses pre-programmed computer software to control the movement of machinery. This process ensures high precision, consistency, and the ability to create complex shapes and patterns, making it ideal for crafting detailed gear designs for watch dials and kitchen parts.

3. **Can these parts be customized to specific designs?**

Yes, one of the key advantages of CNC machining is its flexibility in customization. Customers can provide their own designs or work with manufacturers to create unique patterns, sizes, and finishes tailored to their specific needs, whether for a watch dial or a kitchen component.

4. **Are these parts suitable for both decorative and functional purposes?**

Absolutely. Custom brass gear watch dials are often used as decorative elements in luxury watches, while CNC-machined kitchen parts can serve both functional and aesthetic roles. For example, brass gears can be incorporated into kitchen gadgets or decorative hardware, blending utility with visual appeal.

5. **How do I maintain and clean brass gear watch dials or kitchen parts?**

Brass requires regular maintenance to retain its shine and prevent tarnishing. Cleaning with a mild soap solution and a soft cloth is recommended. For long-term protection, applying a brass polish or protective coating can help maintain the material’s luster and durability.

Custom brass gear watch dial CNC machining kitchen parts are a perfect blend of artistry and engineering, offering both beauty and functionality for a wide range of applications. Whether for timepieces or culinary tools, these components are designed to impress and endure.

(Custom Brass Gear Watch Dial Cnc Machining Kitchen Part)

REQUEST A QUOTE

RELATED PRODUCTS

Professional Factory Stable Transmission Good Transmission Rate Diesel Engine Gears For The Marine Industry

Manufactory Direct Easy To Disassemble Meticulous Workmanship Engine Camshaft Gear For Construction Machinery

Excavator Final Drive Travel Motor Parts Carrier Assy Reduction gear Box Sun gear

Metallurgy powder customized High precision Stainless Steel Iron bronze Sintered plastic drive gear and spur gear

Customized Bonfiglioli 306 series Hydraulic high Speed Reduction Gearbox Gear AC Motor Cycloidal Reducer planetary Gear Reducer