PRODUCT PARAMETERS

Description

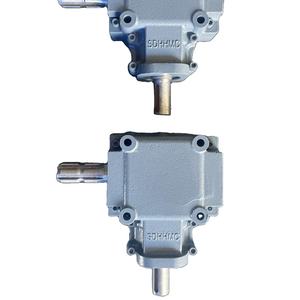

Overview of Custom Mining High Transmission Speed Gear Box Reducer Helical gear Wheel

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of Custom Mining High Transmission Speed Gear Box Reducer Helical gear Wheel

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: Custom Mining High Transmission Speed Gear Box Reducer Helical gear Wheelsystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern Custom Mining High Transmission Speed Gear Box Reducer Helical gear Wheelmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(Custom Mining High Transmission Speed Gear Box Reducer Helical gear Wheel)

Specifications of Custom Mining High Transmission Speed Gear Box Reducer Helical gear Wheel

The Custom Mining High Transmission Rate Gear Box Reducer Helical Gear Wheel is crafted to deliver durable efficiency popular mining procedures. Including a helical gear style, it makes certain smooth, peaceful operation with high torque transmission efficiency. The helical teeth involve gradually, reducing shock loads and lessening wear, which improves longevity in heavy-duty applications. The gearbox is constructed from high-strength alloy steel, heat-treated for exceptional solidity (HRC 58-62) and fatigue resistance, making sure longevity under extreme problems.

Transmission speed is optimized for mining equipment, with input speeds varying approximately 3,000 RPM and outcome rates adjustable via adjustable equipment proportions (commonly 5:1 to 30:1). This adaptability sustains exact rate control for crushers, conveyors, and excavators. The gearbox flaunts a load ability of approximately 500 kN, fitting high radial and axial tons typical in mining atmospheres. Its portable, modular style enables seamless assimilation right into existing systems while lowering installment footprint.

Trick specifications consist of a transmission performance of 95-98%, achieved via precision-ground equipments and advanced lubrication systems. The housing is constructed from actors iron or pliable steel, supplying extraordinary strength and resistance to resonance. IP65-rated securing makes certain defense versus dirt, dampness, and contaminants, important for below ground or open-pit mining. Optional finishings or nitride treatments improve deterioration resistance in extreme environments.

Thermal monitoring is focused on with incorporated air conditioning fins or optional forced-air air conditioning to preserve ideal operating temperatures (-20 ° C to 120 ° C). The transmission works with conventional mining electric motor interfaces (IEC or NEMA) and supports bidirectional procedure. Sound degrees are kept listed below 75 dB(A) as a result of the helical equipment’s fundamental sound decrease residential or commercial properties.

Modification alternatives include customized shaft sizes (20-200 mm), flange setups, and placing orientations. Reaction is reduced to ≤ 15 arc-min for accuracy applications. Upkeep is streamlined with available evaluation ports and grease-lubricated bearings rated for 10,000+ hours of service.

Certified with ISO 9001, CE, and MSHA security requirements, this transmission is created for 24/7 operation, using a life span of over 10 years with proper upkeep. Suitable for heavy-load, high-speed mining equipment, it incorporates reliability, performance, and adaptability to optimize performance in one of the most challenging settings.

(Custom Mining High Transmission Speed Gear Box Reducer Helical gear Wheel)

Applications of Custom Mining High Transmission Speed Gear Box Reducer Helical gear Wheel

The Customized Mining High Transmission Speed Transmission Reducer with Helical Equipment Wheel is crafted to satisfy the rigorous demands of modern-day mining procedures, providing unmatched efficiency in high-torque, high-speed applications. Its innovative helical gear style guarantees smooth, effective power transmission while minimizing noise, vibration, and wear. This reducer is excellent for sturdy equipment utilized in mining, such as conveyors, crushers, excavators, and exploration gears, where reliability and toughness are important.

One of the main applications of this gear reducer remains in product handling systems. Mining procedures count on conveyor belts to transfer bulk materials over cross countries, typically under severe lots. The helical equipment wheel’s angled teeth make it possible for steady involvement, reducing shock tons and boosting the life-span of both the gearbox and linked devices. Its high transmission speed capacity ensures constant throughput, even in high-capacity mining environments.

In crushing and grinding machinery, the reducer’s ability to manage high rotational speeds and torque variations makes it indispensable. The helical gears disperse lots uniformly across the tooth surface area, stopping local anxiety and expanding solution intervals. This is critical in mineral processing, where devices operates constantly under unpleasant conditions. The precision-machined components and robust real estate additionally safeguard against dirt, moisture, and mechanical effects common in mining websites.

An additional key application remains in boring equipment. The gear reducer’s high-speed transmission makes certain effective power distribution to drill heads, enabling much faster infiltration rates in hard rock developments. The helical style minimizes power loss, boosting total operational performance and minimizing gas or power intake in diesel or electric-driven systems.

Customization choices permit this transmission to be customized to details mining requirements, including varying ratios, shaft configurations, and product upgrades for harsh or high-temperature environments. Its small layout and convenience of integration with existing equipment make it a functional solution for both surface and below ground mining operations.

By integrating high-speed performance, durability, and versatility, the Custom Mining Helical Transmission Reducer enhances productivity, decreases downtime, and reduces upkeep expenses, making it an essential element in optimizing mining operations. Its crafted durability guarantees it holds up against the harshest problems while keeping precision and performance.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Custom Mining High Transmission Speed Gear Box Reducer Helical gear Wheel

**1. What makes helical gear wheels ideal for custom mining gear reducers?**

Helical gear wheels are preferred in mining gear reducers due to their angled teeth, which provide smoother, quieter operation compared to spur gears. This design ensures even load distribution, reducing wear and tear in high-transmission-speed applications. Their durability and efficiency in handling heavy loads and shock conditions make them ideal for harsh mining environments.

**2. How does high transmission speed impact mining operations?**

High transmission speed in gear reducers enables faster machinery cycles, boosting productivity in processes like drilling, crushing, or material transport. Custom helical gear reducers are engineered to maintain stability at elevated speeds, minimizing vibrations and heat buildup, which are critical for avoiding downtime in continuous mining operations.

**3. Can these gear reducers be customized for specific mining equipment?**

Yes. Custom mining gear reducers are tailored to fit unique machinery requirements, including torque ratings, shaft orientations, and mounting configurations. Helical gear wheels can be adjusted in terms of size, material (e.g., hardened steel), and gear ratios to align with specific operational demands, ensuring compatibility and peak performance.

**4. What maintenance is required for helical gear reducers in mining?**

Regular lubrication and inspection are essential. Helical gears’ design reduces friction, but mining environments expose components to dust, moisture, and debris. Sealed housings and high-quality lubricants help extend service life. Periodic checks for alignment, tooth wear, and bearing conditions prevent unexpected failures.

**5. How do these gearboxes handle extreme mining conditions?**

Custom helical gear reducers are built with robust materials like alloy steels and feature advanced heat treatment processes (e.g., carburizing) to enhance hardness and fatigue resistance. Their design ensures reliable performance under heavy loads, high temperatures, and variable speeds, making them suitable for underground or open-pit mining applications.

(Custom Mining High Transmission Speed Gear Box Reducer Helical gear Wheel)

REQUEST A QUOTE

RELATED PRODUCTS

Genuine K19 K38 K50 NT855 NTA855 VTA28 N14 LT10 M11 QSK19 QSK38 QSK45 QSK60 Crankshaft Gear and Crankshaft For Cummins

Good quality cnc processing self lubricating MC nylon POM industrial wear resistant transmission gearbox plastic gear rack

s High Precision Cnc Milling Turning Service Steel Bevel Gears Custom Spur Gears Sets

High Quality Hydraulic Gear Pump for Forklift Power Units

Gear Manufacturing Custom Cnc Machining Services For Precision Spur And Steel Gears Tailored For Oem Fabrications