PRODUCT PARAMETERS

Description

Overview of Excavator Final Drive Travel Motor Parts Carrier Assy Reduction gear Box Sun gear

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of Excavator Final Drive Travel Motor Parts Carrier Assy Reduction gear Box Sun gear

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: Excavator Final Drive Travel Motor Parts Carrier Assy Reduction gear Box Sun gearsystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern Excavator Final Drive Travel Motor Parts Carrier Assy Reduction gear Box Sun gearmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(Excavator Final Drive Travel Motor Parts Carrier Assy Reduction gear Box Sun gear)

Specifications of Excavator Final Drive Travel Motor Parts Carrier Assy Reduction gear Box Sun gear

The Excavator Final Drive Travel Electric Motor Components Carrier Assy Decrease Gear Box Sunlight Gear is a crucial element in sturdy excavators, created to transform hydraulic power right into mechanical movement for efficient travel and procedure. The last drive travel motor is built with high-strength steel real estate, guaranteeing longevity under severe loads and rough atmospheres. It normally includes a axial piston electric motor layout with a variation variety of 150-500 cc/rev, creating torque outputs between 15,000 to 50,000 Nm, depending upon the excavator model. The motor runs at rates of 10-30 RPM, enhanced for smooth grip and accurate control. Sealing systems consist of multi-lip seals and O-rings ranked for IP67 protection, avoiding contamination from dust, water, and debris. The Carrier Assy (Carrier Setting up) incorporates global gears and bearings, constructed from heat-treated alloy steel (e.g., 20CrMnTi) for high wear resistance. It supports the reduction transmission, which utilizes a multi-stage worldly equipment system with a decrease proportion of 20:1 to 50:1, minimizing motor speed while magnifying torque. The sun equipment, a central element of the worldly gear collection, is precision-machined from case-hardened alloy steel (HRC 58-62) to withstand high cyclic anxieties. Its tooth profile is crafted for optimum tons distribution, lessening wear and noise. The decrease transmission real estate is made of ductile iron or created steel, with machined flanges for seamless integration right into the track framework. Lubrication channels ensure efficient oil circulation to equipments and bearings, compatible with ISO VG 68 or SAE 10W-30 hydraulic oils. The assembly is checked for axial and radial lots capabilities up to 200 kN and 150 kN, respectively, making certain integrity sought after applications like mining and construction. All elements fulfill ISO 9013 and cacophony criteria for dimensional accuracy and efficiency. Compatibility reaches significant excavator brand names (CAT, Komatsu, Hitachi) with screw patterns standardized to match OEM specs. Maintenance intervals suggest examination every 2,000 operating hours, with a service life exceeding 10,000 hours under normal problems.

(Excavator Final Drive Travel Motor Parts Carrier Assy Reduction gear Box Sun gear)

Applications of Excavator Final Drive Travel Motor Parts Carrier Assy Reduction gear Box Sun gear

The excavator last drive traveling motor parts, consisting of the Carrier Assy, Decrease Transmission, and Sun Equipment, are important elements that make certain the effective operation of durable equipment popular atmospheres. These components work together to transform hydraulic power from the excavator’s motor right into mechanical pressure, allowing exact movement, torque generation, and load administration. Right here’s a failure of their vital applications:

** Carrier Assy **: This element acts as the architectural backbone of the final drive setting up, housing and lining up planetary equipments, bearings, and shafts. It guarantees stability during high-stress operations like digging, training, or going across unequal terrain. Applications include mining, construction, and forestry, where the Service provider Assy’s toughness sustains continual operation under heavy loads and rough problems.

** Reduction Transmission **: Developed to take care of torque conversion, this transmission lowers high-speed electric motor turnings into slower, high-torque result for the excavator’s tracks. This is important for jobs calling for controlled power, such as climbing up slopes, pushing heavy debris, or operating in sloppy or rocky settings. Its precision design ensures smooth power transmission, reducing endure other drivetrain components.

** Sun Equipment **: As the main equipment in the global decrease system, the Sunlight Gear connects with worldly gears to distribute rotational force equally. This configuration enhances efficiency in applications like trenching, demolition, or product handling, where regular power distribution is important. The Sunlight Equipment’s heat-treated steel building and construction withstands deformation, extending life span even under extreme anxiety.

With each other, these parts enable excavators to execute dependably in markets varying from farming to infrastructure growth. Their robust style minimizes downtime in harsh problems, while precision machining ensures optimal fuel efficiency and reduced operational prices. Normal upkeep of these parts– such as lubrication and examination for wear– prolongs their life expectancy, making certain continuous efficiency. Whether in mining procedures requiring deep excavation or metropolitan building projects requiring exact movement, the Carrier Assy, Reduction Gear Box, and Sunlight Gear develop the foundation of excavator performance, providing power, longevity, and versatility throughout diverse applications.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Excavator Final Drive Travel Motor Parts Carrier Assy Reduction gear Box Sun gear

What is the function of the sun gear in an excavator final drive travel motor? The sun gear is a critical component within the planetary gear system of the reduction gearbox. It transfers torque from the travel motor to the planetary gears, reducing rotational speed while increasing torque output to the excavator’s tracks. This ensures efficient power transmission, enabling smooth movement and heavy-load handling.

What are the signs of a failing sun gear or reduction gearbox? Common symptoms include grinding or whining noises during operation, reduced excavator mobility, excessive vibration, or visible metal shavings in the gear oil. Overheating of the final drive or uneven track movement may also indicate wear, misalignment, or damage to the sun gear, planetary gears, or carrier assembly.

How can I maintain the sun gear and reduction gearbox? Regularly check and replace gear oil to prevent contamination. Ensure proper lubrication levels and use manufacturer-recommended oils. Inspect seals for leaks and address them promptly to avoid debris ingress. Schedule routine inspections for wear, cracks, or pitting on gear teeth, and tighten loose bolts in the carrier assembly to prevent misalignment.

Can a damaged sun gear be repaired, or does it require replacement? Minor wear or surface damage can sometimes be repaired through machining or polishing. However, severe pitting, chipped teeth, or cracks typically require complete replacement. Using a damaged sun gear risks further harm to the planetary system, carrier assembly, or motor, leading to costly downtime. Always assess damage severity with a professional.

Where should I source replacement sun gears or carrier assembly parts? Purchase genuine OEM parts or high-quality aftermarket equivalents from trusted suppliers. OEM parts guarantee compatibility, durability, and precise engineering for your excavator model. Reputable suppliers provide warranties and technical support, ensuring optimal performance and longevity of the final drive system. Avoid uncertified vendors to prevent part failures.

(Excavator Final Drive Travel Motor Parts Carrier Assy Reduction gear Box Sun gear)

REQUEST A QUOTE

RELATED PRODUCTS

9057914 Auto parts car Gear Shift Knob Head Handle Lever Shift control handball For Buick Excelle

K series bevel helical gearbox bevel gear box reducer reductor stm 100 ( 90 – b5 ) bevel gearbox rack pinion lift motor

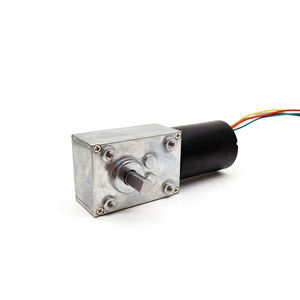

geared motors gearbox reducer drive power transmission shaft gearbox Helical Worm Gear Reducer Motor

Aluminum casting customized OEM precision manufacturing high pressure casting gearbox valve plate piston

YTO tractor gear YTO-X704/804/904 YTO tractor sliding gear 885145164SZ/1.32.106