PRODUCT PARAMETERS

Description

Overview of Factory direct s of various gear parts

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of Factory direct s of various gear parts

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: Factory direct s of various gear partssystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern Factory direct s of various gear partsmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

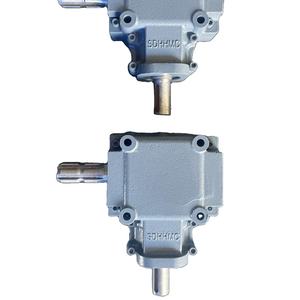

(Factory direct s of various gear parts)

Specifications of Factory direct s of various gear parts

Factory-direct gear parts are precision-engineered components designed for durability, efficiency, and seamless assimilation into industrial machinery, automotive systems, robotics, and hefty tools. These equipments are made making use of innovative CNC machining, hobbing, grinding, and heat-treatment processes to guarantee high performance and longevity. Products include alloy steels (e.g., 4140, 4340), stainless-steel, brass, nylon, and specialty polymers, picked based upon application requirements such as tons capability, corrosion resistance, or sound reduction. Typical equipment types include spur equipments, helical gears, bevel gears, worm gears, and rack-and-pinion sets, each readily available in customized or common arrangements.

Stimulate equipments feature straight teeth and are perfect for low-speed, high-torque applications, with modules varying from 1 to 10 and sizes approximately 500 mm. Helical gears, with tilted teeth for smoother procedure, assistance higher speeds and lots, readily available in helical angles of 15 °– 45 ° and face sizes approximately 200 mm. Bevel equipments are made for converging shafts at 90 °, with spiral or straight teeth, precision-ground for marginal backlash. Worm equipments supply high reduction proportions (as much as 100:1) and self-locking capabilities, with set steel worms paired with bronze or light weight aluminum alloy wheels.

Tons abilities differ by equipment kind, with torque ratings from 10 Nm to 10,000 Nm, depending upon product and style. Surface firmness for steel gears ranges from 45– 65 HRC, achieved with carburizing, nitriding, or induction hardening. Dimensional precision sticks to AGMA Course 8– 10 or ISO 6– 8 criteria, with tooth account resistances as limited as ± 0.005 mm. Birthed dimensions are customizable (5– 200 mm), with keyways, splines, or set-screw configurations.

Customization choices consist of bespoke tooth accounts, coatings (zinc, nickel, PTFE), and adjustments for noise reduction or vibration damping. Gears undertake rigorous quality checks, including CMM measurements and backlash testing, guaranteeing compliance with sector certifications like ISO 9001. Applications extend auto transmissions, conveyor systems, wind generators, and aerospace actuators. Factory-direct pricing removes middlemans, supplying expense savings of 20– 30% contrasted to retail suppliers, with preparations as brief as 1– 2 weeks for standard gears. Packaging includes anti-corrosion therapies and shock-resistant crating for worldwide shipping. Technical assistance and CAD illustrations are provided to help with combination.

(Factory direct s of various gear parts)

Applications of Factory direct s of various gear parts

Factory-direct sales of gear components offer a streamlined strategy for industries to resource high-quality, custom-engineered components directly from producers, getting rid of middlemans and reducing costs. Gears are basic in transmitting motion and power across equipment, and factory-direct purchase guarantees precision, integrity, and customized solutions for varied applications. Right here’s an overview of essential sectors leveraging factory-direct gear components:

** Automotive and Transport: ** Gear components such as spur equipments, helical gears, and differential equipments are important in transmissions, engines, and steering systems. Factory-direct providers give OEMs and aftermarket companies with sturdy, high-torque equipments that satisfy rigid automotive standards. Modification makes certain compatibility with hybrid and electrical lorry systems, enhancing efficiency and performance.

** Industrial Machinery: ** Heavy-duty gear shelfs, worm gears, and planetary equipments are used in manufacturing devices, conveyor systems, and CNC makers. Straight sourcing permits factories to purchase equipments wholesale with details resistances, products (like solidified steel or corrosion-resistant alloys), and warm treatments to stand up to high lots and continuous operation.

** Robotics and Automation: ** Accuracy equipments, including harmonic drives and bevel equipments, enable precise activity control in robot arms, automated assembly lines, and medical robots. Factory-direct makers supply portable, light-weight layouts with marginal backlash, crucial for high-speed, repeatable tasks in markets like electronics and drugs.

** Renewable Energy: ** Wind generators and solar tracking systems count on large-diameter equipments and slewing rings to transform natural power right into power. Factory-direct sales provide affordable, durable remedies designed to sustain severe environmental conditions, reducing downtime and maintenance costs.

** Aerospace and Protection: ** Airplane landing gear, rocket systems, and radar tools call for ultra-precise, light-weight equipments made from sophisticated composites or titanium. Direct partnerships with producers make sure compliance with strenuous safety and security and performance requirements, with alternatives for quick prototyping and screening.

** Marine and Agriculture: ** Corrosion-resistant gears for ship engines and watering systems are tailored to deal with moisture, saltwater, and heavy loads. Farmers and aquatic designers gain from factory-direct pricing and quick substitutes for used parts.

By buying equipment components factory-direct, organizations access to technological proficiency, shorter preparations, and scalable production. Customization options, from gear tooth accounts to lubrication requirements, ensure optimum performance for specialized applications. Removing representatives likewise reduces expenses, making it much easier for sectors to maintain competitive edges while making sure machinery long life and effectiveness.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Factory direct s of various gear parts

What are the benefits of buying gear parts directly from a factory? Purchasing gear parts directly from a factory eliminates middleman costs, ensuring competitive pricing. Factories often offer bulk-order discounts, customization options, and faster lead times due to streamlined production processes. Direct communication with manufacturers also ensures clarity in specifications and quality control, reducing errors.

How do I ensure the quality of factory-direct gear parts? Reputable factories provide material certifications (e.g., ISO, ASTM) and conduct rigorous testing (hardness, tensile strength, dimensional checks). Request samples, inspect manufacturing facilities virtually or in person, and review client testimonials. Many factories also offer warranties or guarantees on their products to assure quality and durability.

Can I request custom gear parts tailored to my needs? Yes. Most factories specialize in custom gear manufacturing, offering modifications in material, size, tooth profile, or load capacity. Provide detailed drawings or specifications, and engineers will collaborate to refine designs. Custom orders may require longer lead times and minimum order quantities (MOQs), depending on complexity.

What is the typical lead time for factory-direct gear parts? Standard gear parts ship within 2–4 weeks, while custom designs may take 6–12 weeks. Lead times depend on order volume, material availability, and production schedules. Factories often expedite orders for urgent needs, though additional fees may apply. Always confirm timelines before placing orders.

Do factories offer after-sales support for gear parts? Many factories provide technical support, replacement services, and troubleshooting for defective or underperforming parts. Warranty periods vary (commonly 1–2 years) and cover manufacturing defects. Ensure terms are clear in the purchase agreement. Some suppliers also assist with maintenance tips or integration guidance for optimal performance.

(Factory direct s of various gear parts)

REQUEST A QUOTE

RELATED PRODUCTS

New Ball Gear Knob for Agricultural Machinery CNC Used Core Components for Engine Machine Tools Accessories

Custom Heavy Excavator Gearbox Main Drive Helical Large Pinion Wheel Shaft Forging Steel Large Gear And Shaft Assembly

K series bevel helical gearbox bevel gear box reducer reductor stm 100 ( 90 – b5 ) bevel gearbox rack pinion lift motor

RF YUEFU High Quality Durable Clutch Gear White Washing Machine Clutch Gear For Hitachi

Aluminum Alloy Stainless Steel Wheel Accessories Primary Gear Wheel Bearing Gear