PRODUCT PARAMETERS

Description

Overview of High Accuracy OEM Machining Cnc Milling Transmission Part Oxide Black Stainless Steel Wheel Spur gear

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of High Accuracy OEM Machining Cnc Milling Transmission Part Oxide Black Stainless Steel Wheel Spur gear

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: High Accuracy OEM Machining Cnc Milling Transmission Part Oxide Black Stainless Steel Wheel Spur gearsystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern High Accuracy OEM Machining Cnc Milling Transmission Part Oxide Black Stainless Steel Wheel Spur gearmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(High Accuracy OEM Machining Cnc Milling Transmission Part Oxide Black Stainless Steel Wheel Spur gear)

Specifications of High Accuracy OEM Machining Cnc Milling Transmission Part Oxide Black Stainless Steel Wheel Spur gear

The High Accuracy OEM Machining CNC Milling Transmission Part Oxide Black Stainless Steel Wheel Spur Gear is engineered for precision, sturdiness, and performance popular industrial applications. Crafted from top-quality stainless steel, normally 304 or 316, this spur gear provides phenomenal rust resistance, stamina, and long life. The oxide black surface therapy enhances appearances while offering an additional layer of security versus wear, oxidation, and ecological elements, making it ideal for rough operating problems.

Key requirements include customizable measurements to fulfill OEM demands, with basic choices covering diameters ranging from 10mm to 500mm, bore dimensions from 5mm to 100mm, and modules in between 1 and 10. Teeth setups are precision-cut through CNC milling, guaranteeing tight tolerances (ISO 1328 or AGMA 2000 criteria) with common precision within ± 0.01 mm. The equipment’s pressure angle is standard at 20 levels for optimal load circulation, though custom-made angles are offered. Heat therapy processes, such as quenching and tempering, achieve a firmness of 40-50 HRC, stabilizing strength and put on resistance.

The oxide black coating is applied through a chemical conversion process, producing an attire, non-reflective surface area that reduces rubbing and stands up to damaging. Surface area roughness is kept at Ra ≤ 0.8 μm to make certain smooth meshing and decreased sound throughout operation. These equipments are evaluated for dimensional precision, material honesty, and lots capability, with rigorous QA protocols consisting of CMM assessment and torque testing.

Designed for applications in auto transmissions, robotics, aerospace systems, and industrial machinery, these spur equipments manage high torque and rotational rates while preserving accuracy. Customization alternatives include tooth profiling, birthed keyways, and flange adjustments. Conformity with RoHS and REACH requirements makes sure environmental and safety and security adherence.

Each equipment is separately packaged in anti-corrosive materials, with mass orders sustained by customized crating for secure shipping. OEM collaborations take advantage of adaptable order amounts, rapid prototyping, and technical support. Backed by ISO 9001-certified production, this oxide black stainless steel spur equipment incorporates sophisticated design with reliability, making it a critical element for high-performance mechanical systems.

(High Accuracy OEM Machining Cnc Milling Transmission Part Oxide Black Stainless Steel Wheel Spur gear)

Applications of High Accuracy OEM Machining Cnc Milling Transmission Part Oxide Black Stainless Steel Wheel Spur gear

High Accuracy OEM Machining CNC Milling Transmission Component Oxide Black Stainless-steel Wheel Spur Gear is a precision-engineered part developed for requiring applications where integrity, sturdiness, and aesthetic appeal are important. Made utilizing advanced CNC milling technology, this spur gear accomplishes limited tolerances and smooth tooth accounts, making certain seamless meshing and efficient power transmission in mechanical systems. The use of state-of-the-art stainless steel gives outstanding toughness, put on resistance, and long life, while the oxide black finish boosts rust defense and adds a smooth, modern-day appearance appropriate for both industrial and consumer-facing atmospheres.

In automotive systems, this spur equipment is suitable for transmissions, engine parts, and drivetrain assemblies, where its precision decreases noise and resonance while enhancing gas effectiveness. The oxide black finish additionally enhances custom or high-end vehicle layouts. Industrial equipment gain from its capability to take care of hefty loads in conveyor systems, packaging equipment, and production devices, with stainless steel’s resistance to extreme chemicals and severe temperature levels ensuring very little downtime. Aerospace applications utilize the gear’s light-weight durability for actuators, landing gear mechanisms, and control systems, where failure is not a choice.

Robotics and automation depend on its high accuracy for specific activity control in robot arms, CNC machines, and production line, guaranteeing repeatability in high-speed procedures. The medical industry uses these equipments in imaging devices, surgical devices, and analysis devices, where stainless steel’s sanitary residential properties and rust resistance satisfy strict sanitation needs. Renewable resource systems, such as wind turbines and solar tracking units, utilize the equipment’s effectiveness to sustain outside exposure while maintaining efficiency.

Custom-made OEM services are available, allowing customized measurements, tooth profiles, or load capabilities to fit certain applications. The oxide black coating not only boosts visual appeals however also decreases upkeep by resisting corrosion and use in humid or corrosive atmospheres. Combining CNC accuracy, material excellence, and practical style, this spur gear is a flexible service for markets prioritizing efficiency, toughness, and aesthetic quality.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of High Accuracy OEM Machining Cnc Milling Transmission Part Oxide Black Stainless Steel Wheel Spur gear

1. **What are the key benefits of using Oxide Black Stainless Steel for CNC-milled spur gears?**

Oxide Black Stainless Steel offers superior corrosion resistance, high durability, and a sleek aesthetic finish. The oxide black coating enhances surface hardness, reducing wear and friction during operation. Stainless steel itself provides excellent mechanical strength, making it ideal for high-stress transmission applications. This combination ensures longevity, minimal maintenance, and reliable performance in harsh environments.

2. **How precise are these CNC-milled spur gears?**

Our high-accuracy OEM machining process guarantees tight tolerances, typically within ±0.01 mm. Advanced CNC milling technology ensures consistent tooth profile geometry, optimal meshing, and smooth power transmission. Each gear undergoes rigorous quality checks, including coordinate measuring machines (CMM) and surface roughness tests, to meet industry standards for precision and performance.

3. **Can these spur gears withstand high-temperature or corrosive environments?**

Yes. The oxide black treatment on stainless steel significantly improves resistance to oxidation, moisture, and chemical exposure. The material retains its structural integrity in temperatures up to 400°C (752°F), making it suitable for automotive, aerospace, and industrial machinery applications where thermal stability and corrosion resistance are critical.

4. **Are custom designs or sizes available for these gears?**

Absolutely. As an OEM manufacturer, we specialize in custom CNC milling to match specific requirements. We can produce spur gears in varying diameters, modules, tooth counts, and bore sizes. Provide your technical drawings or specifications, and our team will ensure exact replication, including surface treatments like oxide black coating.

5. **What industries commonly use these stainless steel spur gears?**

These gears are widely used in automotive transmissions, robotics, agricultural machinery, food processing equipment, and precision industrial systems. Their high accuracy, load-bearing capacity, and corrosion resistance make them ideal for applications demanding reliable motion control, minimal backlash, and long-term durability under demanding operational conditions.

(High Accuracy OEM Machining Cnc Milling Transmission Part Oxide Black Stainless Steel Wheel Spur gear)

REQUEST A QUOTE

RELATED PRODUCTS

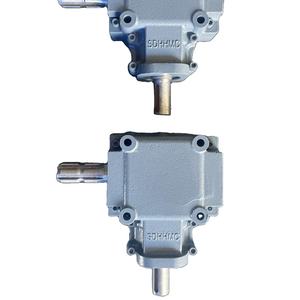

At series Hollow high precision spiral bevel gear right angle gearbox

YTO tractor gear YTO-X704/804/904 YTO tractor sliding gear 885145164SZ/1.32.106

China produce Metal Gear Wheel/ Stainless Steel Spur Gear

High Precision Gear Rack Alloy Steel High Quality Material Gear Rack CNC Machine Tool Industrial Equipment Gear Rack