PRODUCT PARAMETERS

Description

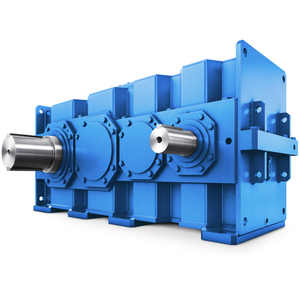

Overview of High-Precision CNC Machining For Aluminum Gear Parts. Professional And Fine Aluminum gear CNC Turning For Mechanical Equipment

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of High-Precision CNC Machining For Aluminum Gear Parts. Professional And Fine Aluminum gear CNC Turning For Mechanical Equipment

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: High-Precision CNC Machining For Aluminum Gear Parts. Professional And Fine Aluminum gear CNC Turning For Mechanical Equipmentsystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern High-Precision CNC Machining For Aluminum Gear Parts. Professional And Fine Aluminum gear CNC Turning For Mechanical Equipmentmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(High-Precision CNC Machining For Aluminum Gear Parts. Professional And Fine Aluminum gear CNC Turning For Mechanical Equipment)

Specifications of High-Precision CNC Machining For Aluminum Gear Parts. Professional And Fine Aluminum gear CNC Turning For Mechanical Equipment

High-precision CNC machining for aluminum gear parts is a critical step in the production process of mechanical equipment made with aluminum components. The ability to produce precise and high-quality parts with minimal errors is crucial, especially in applications that require strict tolerances and accuracy.

One of the key specifications of high-precision CNC machining for aluminum gear parts is the use of high-resolution technology. This ensures that the tool moves accurately and precisely over the part, resulting in minimized distortion and warping. Additionally, the use of precision ball screws and indexing systems helps to ensure that each tooth of the gears is aligned with its neighbor, ensuring maximum efficiency and reducing the risk of misalignment.

Another important specification of high-precision CNC machining for aluminum gear parts is the use of high-speed spindle speeds. This allows for quick and accurate machining of the part, without the need for manual adjustments or corrections. It also enables the machine to work at faster speeds, increasing productivity and efficiency.

In terms of finishing options, high-precision CNC machining for aluminum gear parts typically uses hydrogradate oils or resins to remove metal chips from the surface of the part. These oils and resins help to reduce contamination and ensure a clean finish.

Overall, high-precision CNC machining for aluminum gear parts is an essential component of the manufacturing process. It provides precision, accuracy, and reliability, allowing manufacturers to create high-quality parts quickly and efficiently. By using advanced technology and specifying the right parameters, manufacturers can ensure that their aluminum gear parts meet even the most demanding requirements.

(High-Precision CNC Machining For Aluminum Gear Parts. Professional And Fine Aluminum gear CNC Turning For Mechanical Equipment)

Applications of High-Precision CNC Machining For Aluminum Gear Parts. Professional And Fine Aluminum gear CNC Turning For Mechanical Equipment

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of High-Precision CNC Machining For Aluminum Gear Parts. Professional And Fine Aluminum gear CNC Turning For Mechanical Equipment

1. What is high-precision CNC machining for aluminum gear parts?

High-precision CNC machining is the process of using advanced computer-controlled machinery to create highly precise and detailed designs on aluminum gears. This involves using a combination of advanced tools, techniques, and software to ensure that each part is manufactured with incredible accuracy and consistency.

2. How does high-precision CNC machining work for aluminum gear parts?

The basic idea behind high-precision CNC machining for aluminum gear parts is to use a series of specialized machines and equipment that can perform multiple operations simultaneously on the same piece of metal. This includes features such as coolant systems, dust extraction systems, and automated machine movements that allow the operator to focus on creating complex shapes and details without wasting time or effort.

3. Can high-precision CNC machining be used for all types of aluminum gear parts?

No, not all types of aluminum gear parts require high-precision CNC machining. However, for those that do, it is typically the only method available due to the complexity and precision required in their manufacture.

4. Are there any benefits to using high-precision CNC machining for aluminum gear parts?

Yes, there are several benefits to using high-precision CNC machining for aluminum gear parts. These include increased efficiency, improved quality control, and reduced waste. By using advanced equipment and techniques, it is possible to create intricate and precise designs that meet even the tightest tolerances and specifications.

5. How long does it take to complete a high-precision CNC machining project for aluminum gear parts?

The length of time it takes to complete a high-precision CNC machining project for aluminum gear parts will depend on several factors, including the complexity of the design, the size of the part, and the availability of specialized equipment and skilled operators. However, it is generally recommended to plan for at least a few days to a week for larger projects.

(High-Precision CNC Machining For Aluminum Gear Parts. Professional And Fine Aluminum gear CNC Turning For Mechanical Equipment)

REQUEST A QUOTE

RELATED PRODUCTS

EXCAVATOR 3063843 GEAR FOR EX200-3 EX200-5 CONSTRUCTION MACHINERY PARTS

Durable and Soft Silicone Gear Shifter Protective Sleeve for Your Vehicle

Custom Brass Gear Watch Dial Cnc Machining Kitchen Part

Wpa Right Angle Foot Mounted Solid Shaft Cast Iron Worm Gear Reducer Chain Drive gear Box Reduction Gearbox For

Factory Manufacture Cnc Machining Custom 303 304 316 Stainless Steel Spiral Straight 125m 20 Teeth Bevel Gear