PRODUCT PARAMETERS

Description

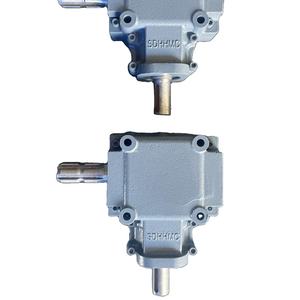

Overview of High Precision Planetary Gearbox Speed Reducer ratio 3/4/5/7/10

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of High Precision Planetary Gearbox Speed Reducer ratio 3/4/5/7/10

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: High Precision Planetary Gearbox Speed Reducer ratio 3/4/5/7/10systems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern High Precision Planetary Gearbox Speed Reducer ratio 3/4/5/7/10manufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(High Precision Planetary Gearbox Speed Reducer ratio 3/4/5/7/10)

Specifications of High Precision Planetary Gearbox Speed Reducer ratio 3/4/5/7/10

The High Precision Planetary Gearbox Speed Reducer is an advanced mechanical component designed to deliver exceptional performance in a wide range of industrial applications. With a compact and robust design, this gearbox offers high torque density, efficiency, and precision, making it ideal for demanding environments. The gearbox is available in multiple reduction ratios, including 3:1, 4:1, 5:1, 7:1, and 10:1, providing flexibility to meet diverse operational requirements.

Constructed with high-quality materials, the gearbox features a planetary gear system that ensures smooth and reliable power transmission. The precision-engineered gears are hardened and ground to minimize wear and extend service life, even under heavy loads and continuous operation. The gearbox is designed to handle high input speeds while maintaining low backlash, ensuring accurate positioning and repeatability in motion control applications.

The housing is made from durable aluminum alloy or cast iron, offering excellent heat dissipation and resistance to corrosion. This makes the gearbox suitable for use in harsh environments, including those with exposure to dust, moisture, or extreme temperatures. The compact and lightweight design allows for easy integration into existing systems, saving space and reducing overall system weight.

The High Precision Planetary Gearbox Speed Reducer is compatible with various types of motors, including servo, stepper, and AC/DC motors, making it a versatile solution for automation, robotics, CNC machinery, and other precision-driven applications. It is also available with optional features such as custom shaft configurations, seals for enhanced protection, and lubrication options to suit specific operational needs.

With its combination of high efficiency, durability, and precision, this gearbox is an excellent choice for industries seeking reliable and long-lasting speed reduction solutions. Whether used in manufacturing, packaging, or material handling, the High Precision Planetary Gearbox Speed Reducer delivers consistent performance and helps optimize system efficiency.

(High Precision Planetary Gearbox Speed Reducer ratio 3/4/5/7/10)

Applications of High Precision Planetary Gearbox Speed Reducer ratio 3/4/5/7/10

High precision planetary gearbox speed reducers with ratios of 3, 4, 5, 7, and 10 are engineered to deliver exceptional performance in a wide range of industrial applications. These gearboxes are designed to provide high torque output, precise speed reduction, and reliable operation, making them ideal for demanding environments where accuracy and durability are critical. Their compact and robust design ensures efficient power transmission while minimizing space requirements, making them suitable for integration into various machinery and equipment.

One of the primary applications of these gearboxes is in robotics and automation systems. The precise speed control and high torque capabilities enable smooth and accurate movement of robotic arms, conveyor systems, and automated assembly lines. The gearboxes’ ability to handle high loads while maintaining precision ensures consistent performance in repetitive tasks, enhancing productivity and reducing downtime.

In the manufacturing sector, these planetary gearboxes are widely used in CNC machines, packaging equipment, and material handling systems. Their ability to achieve specific speed reduction ratios allows for optimal control of machine operations, ensuring high-quality output and efficient production processes. The gearboxes’ high precision and low backlash make them particularly suitable for applications requiring tight tolerances and repeatable motion.

The renewable energy industry also benefits from these gearboxes, particularly in wind turbines and solar tracking systems. The gearboxes’ ability to handle high torque and operate under varying load conditions ensures reliable performance in converting wind or solar energy into usable power. Their durability and low maintenance requirements make them a cost-effective solution for long-term energy generation.

Additionally, these gearboxes are used in medical equipment, such as imaging devices and surgical robots, where precision and reliability are paramount. Their compact design and smooth operation ensure accurate positioning and movement, contributing to the effectiveness of medical procedures.

Overall, high precision planetary gearbox speed reducers with ratios of 3, 4, 5, 7, and 10 are versatile components that enhance the performance of various industrial and commercial applications. Their combination of precision, durability, and efficiency makes them an essential choice for industries seeking reliable and high-performance motion control solutions.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of High Precision Planetary Gearbox Speed Reducer ratio 3/4/5/7/10

A high precision planetary gearbox speed reducer is an essential component in various industrial applications, offering efficient torque transmission and speed reduction with minimal backlash. Here are five frequently asked questions about these gearboxes with speed reduction ratios of 3, 4, 5, 7, and 10:

1. **What is a planetary gearbox, and how does it work?**

A planetary gearbox consists of a central sun gear, multiple planet gears, and an outer ring gear. The planet gears rotate around the sun gear while also revolving within the ring gear, creating a compact and efficient mechanism for torque multiplication and speed reduction. This design ensures high precision, smooth operation, and excellent load distribution.

2. **What are the advantages of using a high precision planetary gearbox?**

High precision planetary gearboxes are known for their compact size, high torque density, and exceptional efficiency. They provide low backlash, ensuring accurate positioning and smooth operation, which is critical in applications like robotics, CNC machinery, and automation systems. Their robust design also allows for high load capacity and long service life.

3. **How do I choose the right speed reduction ratio for my application?**

The speed reduction ratio determines the relationship between input and output speeds. Ratios of 3, 4, 5, 7, and 10 are common options. A lower ratio (e.g., 3:1) is suitable for applications requiring higher output speeds, while a higher ratio (e.g., 10:1) is ideal for applications needing greater torque and slower output speeds. Consider your application’s torque, speed, and load requirements when selecting the ratio.

4. **Can these gearboxes handle high torque and heavy loads?**

Yes, planetary gearboxes are designed to handle high torque and heavy loads due to their multiple gear contact points, which distribute the load evenly. This makes them suitable for demanding applications such as industrial machinery, conveyor systems, and heavy-duty automation equipment.

5. **What maintenance is required for a high precision planetary gearbox?**

These gearboxes are designed for minimal maintenance. Regular lubrication and periodic inspection for wear and tear are typically sufficient to ensure optimal performance. Always follow the manufacturer’s guidelines for lubrication intervals and use the recommended lubricants to extend the gearbox’s lifespan.

High precision planetary gearboxes with speed reduction ratios of 3, 4, 5, 7, and 10 are versatile, reliable, and efficient solutions for a wide range of industrial applications, ensuring smooth operation and precise control.

(High Precision Planetary Gearbox Speed Reducer ratio 3/4/5/7/10)

REQUEST A QUOTE

RELATED PRODUCTS

Factory direct s of 15W 110V 220V 380V electric variable speed control AC gear motor with speed regulator

High precision gear powder metallurgy sintered parts are customized by the powder metallurgy gear

high power gear reducer jzq series zq 250 gearbox zq350 gearbox for conveyor

Factory Direct s Not Easy To Wear Long Service Life Engine Fixed Gear For Loaders

Custom Heavy Excavator Gearbox Main Drive Helical Large Pinion Wheel Shaft Forging Steel Large Gear And Shaft Assembly