PRODUCT PARAMETERS

Description

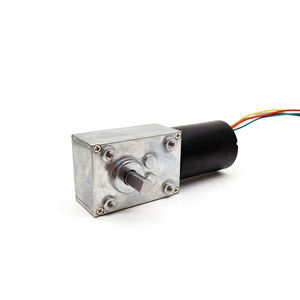

Overview of Machinery engine parts diesel engine gear housing cnc machining milling turning parts

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of Machinery engine parts diesel engine gear housing cnc machining milling turning parts

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: Machinery engine parts diesel engine gear housing cnc machining milling turning partssystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern Machinery engine parts diesel engine gear housing cnc machining milling turning partsmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(Machinery engine parts diesel engine gear housing cnc machining milling turning parts)

Specifications of Machinery engine parts diesel engine gear housing cnc machining milling turning parts

Diesel Engine Gear Housing CNC Machining Milling Turning Parts

Diesel engine gears, especially those used in marine and commercial vehicles, are critical components that require precise。This is where machinery parts such as diesel engine gear housing and milling turning parts come into play.

Diesel engine gear housing is a crucial component that holds the internal components of the engine together and provides stability and support to the engine. It consists of a number of parts, including the cylinder head,, main bearing, water pump, fuel tank, etc. The gear housing is usually made of durable materials such as steel or aluminum, which provide resistance to corrosion and wear and tear.

Milling turning parts refer to all the machined components that are designed for specific operations, such as drilling, tapping, and cutting. These parts can include shafts, bushes, bearings, gears, and other components that are essential for engine operation. CNC machining refers to the process of using computer-aided design (CAD) software to create intricate shapes and designs on a computer-aided (CAM) system.

CNC machining is a highly skilled and time-consuming process that requires expertise in machine tool operation, programming, and troubleshooting. However, it offers precision and consistency in results compared to traditional manual methods. It also allows for greater flexibility in customization and can produce parts with complex geometries that cannot be achieved by hand.

In conclusion, machinery parts such as diesel engine gear housing and milling turning parts are vital components that ensure proper functioning of a vehicle’s engine. They require precise and consistent to ensure optimal performance and longevity. While CNC machining can be a time-consuming and expensive process, it offers benefits such as increased efficiency and reduced risk of errors. Therefore, manufacturers should prioritize investing in high-quality machinery parts to meet their production requirements.

(Machinery engine parts diesel engine gear housing cnc machining milling turning parts)

Applications of Machinery engine parts diesel engine gear housing cnc machining milling turning parts

Diesel engines are an essential part of many modern vehicles and machinery systems. They require precise and reliable components to function correctly, including gear housing. Engine gears, in particular, play a crucial role in maintaining the correct speed and torque of the engine.

Gear housing is a component that houses the gears and other important mechanical parts of the engine. It helps ensure that the gears work together smoothly and efficiently, allowing for efficient power transfer from the engine to the wheels. CNC machining is one of the most popular methods used to manufacture gear housings for diesel engines.

CNC machining involves using computer-aided design (CAD) software to create detailed designs for the gear housing. This allows manufacturers to create precise and accurate components, reducing the risk of defects or errors during manufacturing. Once the design has been finalized, the。

Milling turning parts is another application of machinery engine parts diesel engine gear housing cnc machining milling turning parts. Milling involves using a rotating tool to remove material from a workpiece. In the case of gear turning parts, milling can be used to create complex shapes that would otherwise be difficult to.

Milling can also be used to smooth out rough edges on gears and other mechanical components, ensuring that they are free of burrs or other imperfections. By using CNC machining to manufacture gear housings, manufacturers can reduce the time and cost associated with traditional manufacturing methods.

In conclusion, machinery engine parts diesel engine gear housing cnc machining milling turning parts are critical components of modern vehicle and machinery systems. CNC machining offers several benefits over traditional manufacturing methods, including precision, efficiency, and reduced waste. As technology continues to advance, we can expect to see even more innovative applications of machinery in the future.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Machinery engine parts diesel engine gear housing cnc machining milling turning parts

1. What is the purpose of diesel engine gear housing?

The diesel engine gear housing is a critical component in the engine’s mechanical system. It provides structural support for the various gears and bearings used within the engine, allowing for efficient and smooth operation of the engine.

2. How does CNC machining fit into the process of removing engine gears from engine gear housing?

CNC machining involves using computer-controlled machinery to create precise and accurate machined components. In the case of removing engine gears from engine gear housing, this type of machining is often used to remove individual gears or entire components without damaging surrounding parts.

3. What are the benefits of using a CNC machining shop for engine gearhousing removal?

Using a CNC machining shop can offer several benefits for engine gearhousing removal, including increased accuracy and consistency, reduced waste, and faster and more efficient processing times.

4. Can I remove engine gears from engine gear housing myself with basic tools and equipment?

While it is possible to remove engine gears from engine gear housing using basic tools and equipment, it is important to have prior knowledge of the gears’ specific design and layout in order to accurately identify and remove them safely and efficiently.

5. Are there any safety precautions that should be taken when removing engine gears from engine gear housing?

When removing engine gears from engine gear housing, it is essential to take proper safety precautions to avoid injury or damage to oneself or others. This may include wearing protective clothing, following established procedures for handling the gears and bearing, and ensuring that all machinery is securely moved and contained before beginning work.

(Machinery engine parts diesel engine gear housing cnc machining milling turning parts)

REQUEST A QUOTE

RELATED PRODUCTS

Gear box Custom casting gear wheel and forging shaft Assembly drive gear shaft

At series Hollow high precision spiral bevel gear right angle gearbox

REVO 721506 Timing Gear Camshaft Phaser Adjuster For Nissan Qashqai RENAULT Megane Engine HRA2 H5F H4B OE 130253326R 1302500Q0D

GUOMAO S39/49/59 AC Worm Gear Motor 220/380V

Professional Factory Nice Quality Steel Plastic Spur Gear Customized Sprocket Cnc Machining Brass Worm Gear