PRODUCT PARAMETERS

Description

Overview of Nylon Coupling Gear Nylon Sleeve Inner Tooth 14-80 NL Coupling Gear Sleeve Non-Standard Customizable Shaft Couplings Gear

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of Nylon Coupling Gear Nylon Sleeve Inner Tooth 14-80 NL Coupling Gear Sleeve Non-Standard Customizable Shaft Couplings Gear

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: Nylon Coupling Gear Nylon Sleeve Inner Tooth 14-80 NL Coupling Gear Sleeve Non-Standard Customizable Shaft Couplings Gearsystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern Nylon Coupling Gear Nylon Sleeve Inner Tooth 14-80 NL Coupling Gear Sleeve Non-Standard Customizable Shaft Couplings Gearmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(Nylon Coupling Gear Nylon Sleeve Inner Tooth 14-80 NL Coupling Gear Sleeve Non-Standard Customizable Shaft Couplings Gear)

Specifications of Nylon Coupling Gear Nylon Sleeve Inner Tooth 14-80 NL Coupling Gear Sleeve Non-Standard Customizable Shaft Couplings Gear

The nylon coupling gear sleeve features a resilient internal tooth style made from high-strength nylon 6 or nylon 66. This product resists wear, rust, and chemical direct exposure. It functions well in wet or severe environments. The internal tooth structure guarantees tight interaction with connected shafts. This boosts torque transmission accuracy. The equipment sleeve fits shaft diameters from 14mm to 80mm. Custom-made dimensions outside this range are readily available. Customers can request non-standard modifications for distinct applications. The sleeve makes up for minor shaft imbalances. This minimizes tension on equipment components. It soaks up vibrations during operation. This lowers noise degrees in mechanical systems. The nylon construction requires no lubrication. Maintenance initiatives lower. The equipment deals with modest to high torque tons. Precise torque capability relies on size and material quality. Temperature level resistance ranges from -30 ° C to 80 ° C. Efficiency stays steady within this array. The light-weight design reduces installation. It replaces heavier steel couplings in lots of scenarios. The product suits commercial equipment, automation systems, and robotics. It connects motors, pumps, and conveyor elements. The inner teeth are precision-molded. This makes certain uniform call with shaft grooves. Wear resistance prolongs service life. Replacement cycles come to be much less constant. Colors consist of natural nylon white or black. Customized colors are optional. The sleeve fits basic shaft couplings. Modifications suit keyways or unique grooves. Electrical insulation residential or commercial properties prevent present leakage. This adds safety in electrically energetic setups. Examining verifies conformity with basic industrial requirements. No hazardous substances are released during usage. Bulk orders obtain reduced pricing. Taste units are readily available for testing. Technical illustrations should be attended to personalized layouts. Manufacturing preparation differ by order size. Product packaging utilizes anti-static products. Storage standards advise completely dry, great problems. Direct sunshine exposure is discouraged. The product ships in enhanced boxes. Damage during transportation is uncommon. Installation instructions feature each purchase. Devices needed consist of standard hand devices. Professional support is recommended for complicated configurations.

(Nylon Coupling Gear Nylon Sleeve Inner Tooth 14-80 NL Coupling Gear Sleeve Non-Standard Customizable Shaft Couplings Gear)

Applications of Nylon Coupling Gear Nylon Sleeve Inner Tooth 14-80 NL Coupling Gear Sleeve Non-Standard Customizable Shaft Couplings Gear

The Nylon Coupling Equipment Nylon Sleeve Inner Tooth 14-80 NL Coupling Equipment Sleeve works as a versatile option for linking revolving shafts in machinery. This item is made from high-quality nylon. The product gives durability. It resists wear in high-stress environments. The design consists of an inner tooth structure. This structure makes sure accurate alignment between shafts. It lowers vibration during procedure. The coupling gear sleeve is adjustable. Customers can readjust dimensions to fit non-standard devices. This makes it optimal for specialized industrial applications.

Nylon offers benefits over metal combinings. It is lighter. This lowers stress on equipment elements. It takes in shocks much better. This safeguards linked tools from abrupt effects. The material withstands deterioration. It executes well in damp or chemically revealed setups. Upkeep requirements are very little. Lubrication is not needed. This conserves time and functional costs.

The internal tooth style boosts torque transmission. It protects against slippage under hefty tons. The 14-80 NL design suits tool to high torque applications. It works in conveyor systems, pumps, and product packaging makers. The sleeve fits securely onto shafts. This makes sure steady power transfer. The nylon sleeve acts as a buffer. It wets noise during operation. This creates quieter work environments.

Personalization is an essential feature. Users define inner sizes, tooth counts, or sleeve lengths. This adjusts the combining to special machinery configurations. Non-standard designs are possible. Producers give customized options without high costs. The item fits markets like automobile, food processing, and robotics.

Installation is straightforward. The sleeve slides onto shafts. No unique devices are required. Replacement fasts. Downtime is lessened. The nylon construction withstands temperatures as much as 120 ° C. It stays functional in varied atmospheres.

The coupling gear sleeve is affordable. It outshines typical steel combinings in lots of scenarios. Its light-weight nature lowers shipping expenditures. Long service life cuts substitute frequency. Services attain dependability without significant financial investments. Compatibility with numerous shaft types includes convenience. This makes the item a practical choice for designers seeking effective power transmission remedies.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Nylon Coupling Gear Nylon Sleeve Inner Tooth 14-80 NL Coupling Gear Sleeve Non-Standard Customizable Shaft Couplings Gear

What is the Nylon Coupling Gear Sleeve used for?

The Nylon Coupling Gear Sleeve connects two rotating shafts in machinery. It transfers motion and torque between shafts while absorbing shocks and vibrations. These couplings work in industrial equipment like pumps, motors, conveyor systems, and automation tools. The inner tooth design ensures precise alignment and smooth power transmission. They suit environments requiring lightweight, corrosion-resistant parts.

Why choose nylon material for this coupling sleeve?

Nylon resists rust, chemicals, and wear better than metal. It reduces noise during operation and needs less maintenance. Nylon is lighter, lowering stress on connected machinery. The material dampens vibrations, protecting equipment from damage. These features make it ideal for industries like food processing or packaging where cleanliness and durability matter.

Can the coupling sleeve be customized for specific needs?

Yes. The 14-80 NL Coupling Gear Sleeve supports non-standard customization. Adjustments include inner diameter, outer diameter, tooth count, and sleeve length. Custom bore sizes or tooth profiles fit unique machinery setups. Provide exact measurements or application details for tailored solutions.

How is the coupling sleeve installed?

Align the two shafts needing connection. Slide the nylon sleeve over the shaft ends, ensuring the inner teeth mesh with both couplings. Secure the sleeve with bolts or set screws. No special tools are required. Check alignment after installation to prevent uneven wear.

What temperatures can the nylon sleeve handle?

The nylon material performs best between -40°C and 120°C. Prolonged exposure to temperatures above 120°C may weaken the sleeve. Avoid direct contact with open flames or high-heat sources. Regular inspection helps detect heat-related wear early.

(Nylon Coupling Gear Nylon Sleeve Inner Tooth 14-80 NL Coupling Gear Sleeve Non-Standard Customizable Shaft Couplings Gear)

REQUEST A QUOTE

RELATED PRODUCTS

High Precision Gear Rack Alloy Steel High Quality Material Gear Rack CNC Machine Tool Industrial Equipment Gear Rack

High Hardness 4140 Material Crown Wheel Spiral Bevel Gear for Sewing Machine

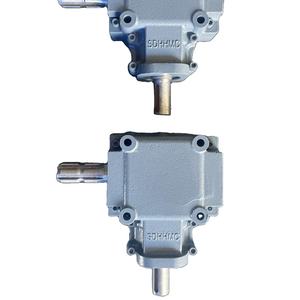

4WG180 6WG180 Mechanical Control Transmission Gearbox Spare Parts WG180 transmission

Tractor Machinery Parts General Part Steering Machine 160B BZZ1-E100C Hydraulic Steering Gear

Aokman Solid Shaft Output Cyclo Gear Motor Cycloidal Gearbox for Power Industrial Transmission