PRODUCT PARAMETERS

Description

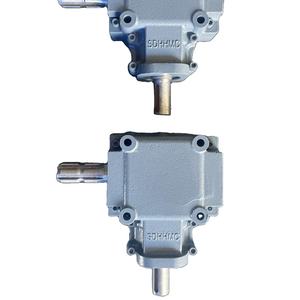

Overview of Precision Worm Gear And Shaft Made In China Gear Wheel Straight Tooth Gear Worm Wheel,Worm Gear,Gear Worm Gear

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of Precision Worm Gear And Shaft Made In China Gear Wheel Straight Tooth Gear Worm Wheel,Worm Gear,Gear Worm Gear

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: Precision Worm Gear And Shaft Made In China Gear Wheel Straight Tooth Gear Worm Wheel,Worm Gear,Gear Worm Gearsystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern Precision Worm Gear And Shaft Made In China Gear Wheel Straight Tooth Gear Worm Wheel,Worm Gear,Gear Worm Gearmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(Precision Worm Gear And Shaft Made In China Gear Wheel Straight Tooth Gear Worm Wheel,Worm Gear,Gear Worm Gear)

Specifications of Precision Worm Gear And Shaft Made In China Gear Wheel Straight Tooth Gear Worm Wheel,Worm Gear,Gear Worm Gear

Accuracy worm equipments and shafts manufactured in China are engineered to provide high performance, durability, and performance in commercial applications. These components, consisting of gear wheels, straight tooth gears, worm wheels, and worm equipments, are developed for smooth power transmission, exact activity control, and long life span. Below are the crucial requirements and functions:

** Materials: ** Made from high-quality materials such as hardened steel alloys, stainless-steel, brass, or aluminum, making certain wear resistance, deterioration security, and stamina. The worm shafts are generally case-hardened or induction-hardened for enhanced surface area toughness.

** Precision Criteria: ** Manufactured to AGMA (American Equipment Manufacturers Association) or ISO requirements, with limited tolerances (IT5 to IT7) to make certain accurate meshing, very little backlash, and ideal torque transmission. Equipment teeth are CNC-machined for consistency and accuracy.

** Tooth Account: ** Straight tooth gears feature involute accounts for efficient power transfer and lowered friction. Worm wheels are developed with helical or globoidal teeth to take full advantage of contact with the worm shaft, enhancing lots distribution and efficiency.

** Load Ability: ** Worm gears and shafts support high torque and axial lots, with load capacities varying from 10 Nm to 500 Nm, depending on size and material. They are suitable for durable applications in machinery, robotics, and vehicle systems.

** Sizes and Dimensions: ** Available in a variety of module dimensions (0.5 to 10 components) and shaft sizes (5 mm to 100 mm). Personalized bore sizes, keyways, and installing setups to fit particular machinery needs.

** Surface area Treatment: ** Options include warmth treatment (carburizing, quenching), nitriding, or zinc plating to boost surface area firmness (as much as 58-62 HRC) and resistance to wear, pitting, and environmental variables.

** Operating Conditions: ** Made for temperature levels varying from -20 ° C to 120 ° C, with lubrication choices (oil or oil) to minimize rubbing and heat generation. Suitable for high-speed (approximately 3000 RPM) and low-noise applications.

** Compatibility: ** Worm equipments and shafts are crafted for seamless combination with electric motors, reducers, and other transmission systems. They are widely made use of in conveyor systems, lifts, product packaging machinery, and CNC equipment.

** Certifications: ** Certified with ISO 9001, CE, and RoHS standards, guaranteeing top quality, safety and security, and ecological obligation.

** Product Packaging and Lead Time: ** Parts are delivered in anti-rust packaging with protective layers. Standard preparation range from 2-4 weeks, with expedited alternatives for mass orders.

These accuracy worm gears and shafts use an economical service for sectors requiring dependable, high-torque activity control. Chinese suppliers integrate innovative production methods with rigorous quality assurance to satisfy worldwide performance criteria.

(Precision Worm Gear And Shaft Made In China Gear Wheel Straight Tooth Gear Worm Wheel,Worm Gear,Gear Worm Gear)

Applications of Precision Worm Gear And Shaft Made In China Gear Wheel Straight Tooth Gear Worm Wheel,Worm Gear,Gear Worm Gear

Precision worm gears and shafts made in China, including gear wheels with straight teeth, worm wheels, worm equipments, and equipment worm gear settings up, are vital elements in a wide range of commercial and mechanical applications. These elements are crafted for high efficiency, sturdiness, and precise movement control, making them important in systems requiring dependable power transmission and torque multiplication. Chinese suppliers take advantage of advanced CNC machining, heat treatment, and quality control procedures to produce worm equipments that meet worldwide requirements while offering affordable solutions.

In the auto field, worm equipments and shafts are utilized in steering systems, electrical car drivetrains, and seat change systems, where smooth procedure and small design are important. Industrial machinery, such as conveyor systems, packaging equipment, and sturdy lifts, counts on these gears for their high load-bearing ability and resistance to use. Robotics and automation systems integrate accuracy worm equipments to attain accurate positioning and repeatable movements, particularly in robotic arms and CNC makers.

Straight-tooth gear wheels, known for their simpleness and efficiency, are generally utilized in applications calling for high-speed turning with minimal noise, such as power tools, agricultural machinery, and fabric devices. Worm wheels and gear worm gear establishes master scenarios demanding right-angle power transmission with a high reduction ratio, consisting of escalators, cranes, and wind turbine pitch control systems. Their self-locking function boosts safety and security in lifts and hoists by preventing backdriving.

The renewable resource industry uses these components in solar tracking systems and wind generators to make certain accurate positioning and optimum power capture. In addition, medical gadgets like MRI devices and surgical robots depend upon the silent, vibration-free procedure of accuracy worm equipments. Chinese-made equipments are also discovered in customer electronic devices, aerospace actuators, and marine propulsion systems, emphasizing their versatility.

By incorporating robust products like set steel or bronze with innovative production methods, Chinese producers supply worm gears and shafts that stabilize performance, longevity, and cost. Customization options, including tailored measurements, layers, and tolerances, further boost their versatility to customized requirements. With a concentrate on technology and international conformity, China’s accuracy gear sector remains to sustain advancements across engineering disciplines worldwide.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Precision Worm Gear And Shaft Made In China Gear Wheel Straight Tooth Gear Worm Wheel,Worm Gear,Gear Worm Gear

What are the key advantages of choosing precision worm gears and shafts made in China? Chinese manufacturers offer high-quality precision worm gears and shafts at competitive prices due to advanced CNC machining, strict quality control, and economies of scale. Products are designed for smooth operation, high torque transmission, and durability, meeting international standards like ISO and AGMA. They are widely used in automation, robotics, and industrial machinery for efficient power transmission and motion control.

How do Chinese manufacturers ensure the quality of worm gears and straight tooth gears? Reputable suppliers use premium materials such as hardened steel, stainless steel, or bronze, combined with heat treatment processes like carburizing or induction hardening to enhance wear resistance. Quality checks include dimensional accuracy testing, surface finish inspections, and load-bearing capacity assessments. Many factories provide certifications (e.g., RoHS, CE) and support third-party inspections to guarantee compliance with global specifications.

Can I request custom specifications for worm wheels or gear worm gears? Yes, most Chinese manufacturers offer customization for worm gears and shafts, including modifications to module size, pressure angle, shaft diameter, and gear ratio. Custom coatings (e.g., zinc, nickel) or lubrication options can also be applied. Provide detailed CAD drawings or samples, and suppliers will tailor products to fit specific applications like automotive systems or conveyor machinery.

What industries commonly use Chinese-made worm gears and gear wheels? These components are integral to industries requiring precise motion control, such as food processing equipment, packaging machinery, medical devices, elevators, and renewable energy systems. Their self-locking capability, compact design, and high reduction ratios make them ideal for applications where space efficiency and reliability are critical.

How does the durability of Chinese worm gears compare to those from other regions? When manufactured using certified materials and proper heat treatment, Chinese worm gears match the performance of gears from Europe or North America. Factors like correct installation, regular lubrication, and adherence to load limits significantly impact lifespan. Many suppliers offer warranties and post-sale support to address wear or operational issues, ensuring long-term reliability in demanding environments.

(Precision Worm Gear And Shaft Made In China Gear Wheel Straight Tooth Gear Worm Wheel,Worm Gear,Gear Worm Gear)

REQUEST A QUOTE

RELATED PRODUCTS

HXMT Spur Gear,Pinion Gear Mod 0.5,0.8,1,1.5,2,etc From China Factory//

Custom Heavy Excavator Gearbox Main Drive Helical Large Pinion Wheel Shaft Forging Steel Large Gear And Shaft Assembly

OEM Custom CNC Lathe Machining Services Turning Aluminum Milling Precision Metal gear CNC Machining Parts CNC Machine Parts

portable small manual mobile 6-25mm hydraulic flexible hose hydraulic crimper gear press crimping machine

metal gear high torque gearboxs 0.25RPM for valve open