PRODUCT PARAMETERS

Description

Overview of steering gear rudder stock wrench Steering gear internal ball joint extractor remover Screw disassembly and assembly t

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of steering gear rudder stock wrench Steering gear internal ball joint extractor remover Screw disassembly and assembly t

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: steering gear rudder stock wrench Steering gear internal ball joint extractor remover Screw disassembly and assembly tsystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern steering gear rudder stock wrench Steering gear internal ball joint extractor remover Screw disassembly and assembly tmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(steering gear rudder stock wrench Steering gear internal ball joint extractor remover Screw disassembly and assembly t)

Specifications of steering gear rudder stock wrench Steering gear internal ball joint extractor remover Screw disassembly and assembly t

The steering gear rudder supply wrench is a specific device developed for the exact modification and upkeep of guiding systems in aquatic and vehicle applications. Built from state-of-the-art, heat-treated steel, this wrench uses outstanding resilience and resistance to rust. It includes a robust jaw layout with a non-slip grasp to safely engage tail stock nuts, making sure risk-free and reliable torque application. The wrench works with typical rudder stock dimensions, typically ranging from 30mm to 100mm, and consists of a strengthened deal with for improved utilize. Its compact style enables very easy accessibility to constrained spaces, making it excellent for shipyards, fixing workshops, and commercial settings.

The guiding gear interior ball joint extractor eliminator is crafted to streamline the elimination and installment of snugly fitted sphere joints within steering systems. Made from set alloy steel, this tool withstands high-pressure removal pressures without deformation. It includes a global clamping system with flexible jaws to fit round joints of differing diameters (15mm to 50mm). The extractor includes a threaded screw mechanism for regulated, gradual force application, minimizing damage to parts. A built-in slide hammer attribute enables quick dislodging of stubborn joints. Its ergonomic manage decreases customer exhaustion throughout long term use, while the anti-rust finishing makes sure longevity in severe environments.

The screw disassembly and setting up tool is a functional device for managing screws in steering gear systems. It features a magnetic little bit owner compatible with Phillips, flathead, Torx, and hexagonal bits, supplying flexibility across numerous screw kinds. The device’s reversible ratchet device allows for rapid clockwise or counterclockwise turning, streamlining both removal and installation procedures. Built from chrome-vanadium steel, it offers high torque ability (as much as 50 Nm) and includes a cushioned hold for enhanced control. The portable, lightweight design guarantees ability to move in tight rooms, while the integrated storage space area keeps little bits arranged.

These tools are vital for keeping guiding system honesty, making certain accurate placement, and minimizing downtime during repair work. They are extensively utilized in automotive repair shops, marine design, and heavy equipment upkeep, offering dependability, safety and security, and efficiency for experts and DIY enthusiasts alike.

(steering gear rudder stock wrench Steering gear internal ball joint extractor remover Screw disassembly and assembly t)

Applications of steering gear rudder stock wrench Steering gear internal ball joint extractor remover Screw disassembly and assembly t

The steering equipment rudder stock wrench is a customized device made for marine and automobile applications, allowing reliable disassembly and assembly of rudder supplies in steering systems. Its robust construction makes certain specific torque application, essential for keeping the integrity of tail elements during maintenance or repairs. This wrench is suitable for shipyards, aquatic designers, and vehicle professionals dealing with guiding gear systems, decreasing downtime by streamlining the elimination of securely secured nuts and bolts in restricted rooms. Its ergonomic design lessens operator tiredness, while heat-treated alloy steel ensures sturdiness under high-stress problems.

The guiding equipment interior round joint extractor eliminator is crafted to deal with challenges in separating confiscated or put on round joints within guiding devices. Frequently utilized in automotive repair shops and industrial maintenance, this device uses regulated pressure to essence sphere joints without damaging surrounding parts. Its flexible jaws and hydraulic-assisted mechanism ensure compatibility with numerous joint sizes, making it important for shock absorber overhauls. The extractor’s hardened steel building and construction stands up to contortion, while its compact design permits access to hard-to-reach locations, improving performance in tasks like tie-rod substitute or guiding transmission maintenance.

The screw disassembly and setting up tool (Screw T) is a versatile option for managing stripped, worn away, or snugly attached screws throughout equipment, electronics, and auto systems. Featuring reverse-threaded extractors and multi-bit compatibility, it allows fast elimination of harmed screws while decreasing surface area marring. Its anti-slip grip and torque-limiting device protect against overtightening throughout reassembly, ensuring thread durability. This tool is widely used in making plants, repair work workshops, and do it yourself settings, providing integrity in applications ranging from engine rebuilds to device maintenance.

Together, these tools streamline complicated jobs in steering gear maintenance, suspension repair work, and screw management. Their accuracy design minimizes component wear, decreases labor prices, and enhances security by reducing manual intervention in high-torque procedures. Whether for marine vessels, vehicles, or commercial devices, these devices are crucial for experts seeking efficiency and longevity in mechanical disassembly and setting up processes.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of steering gear rudder stock wrench Steering gear internal ball joint extractor remover Screw disassembly and assembly t

1. What materials are these tools made of, and are they durable?

The steering gear rudder stock wrench, internal ball joint extractor remover, and screw disassembly/assembly tool are crafted from high-grade heat-treated steel or chrome vanadium for maximum strength and corrosion resistance. These materials ensure durability under heavy loads, repetitive use, and exposure to marine environments. The tools are designed to withstand torque demands during rudder adjustments, ball joint extraction, or screw removal without bending or breaking.

2. Are these tools compatible with all steering gear systems?

Yes, these tools are engineered for universal compatibility with most marine and automotive steering systems. The rudder stock wrench features adjustable jaws or multiple sizing options to fit various rudder stock nuts. The ball joint extractor accommodates standard joint sizes, while the screw tool supports common screw types (e.g., Phillips, hex, or slotted). Always verify measurements against your equipment specs before use.

3. How do I safely remove a seized ball joint or rusted screw?

Apply penetrating oil to loosen rusted components and let it sit for 10–15 minutes. Use the ball joint extractor with a torque wrench for controlled force, ensuring alignment to avoid damage. For stubborn screws, the disassembly tool’s anti-slip grip and hardened tip prevent stripping. Avoid excessive hammering; leverage the tool’s design to distribute pressure evenly and reduce part deformation.

4. Can these tools be used in tight spaces?

The compact, low-profile design of the rudder stock wrench and extractor allows access to confined steering gear compartments. The screw tool includes angled attachments for hard-to-reach screws. Ergonomic handles improve grip in wet or oily conditions, ensuring precise control during disassembly or reassembly without compromising safety.

5. How should I maintain these tools after use?

Clean tools with a degreaser to remove dirt, salt, or debris, then dry thoroughly to prevent rust. Lubricate moving parts (e.g., wrench hinges, extractor threads) with anti-seize grease. Store in a dry environment or protective case. Regularly inspect for wear, especially on gripping surfaces or threads, and replace if damaged to ensure consistent performance and safety.

(steering gear rudder stock wrench Steering gear internal ball joint extractor remover Screw disassembly and assembly t)

REQUEST A QUOTE

RELATED PRODUCTS

Machinery engine parts diesel engine gear housing cnc machining milling turning parts

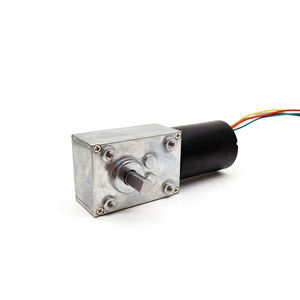

CHENGGANG 0.2KW small reduction gearbox motor Horizontal Asynchronous Motor with brake AC motor with reducer

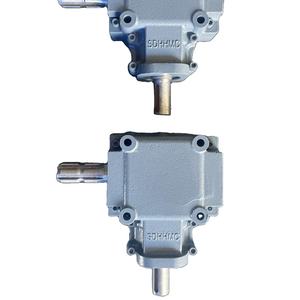

Custom Heavy Excavator Gearbox Main Drive Helical Large Pinion Wheel Shaft Forging Steel Large Gear And Shaft Assembly

Professional Factory Good Tooth Fit Not Easy To Rust Engine Camshaft Gear For The Marine Industry

Tc432-99340 China Tractor Parts Tractor Spare Parts 6-37T Assy Gear Bevel For L4708 L5018